Understanding the operational status of tank hatches and pump jacks at any given time is essential to maintain oil field productivity and regulatory compliance. SignalFire introduces a new multi-purpose wireless inclinometer that can monitor the status of tank hatch position or pump jack motion as part of a SignalFire Remote Sensing System. The patent-pending Tilt SCOUT uses a three-axis sensor that continually monitors angle to detect the orientation of a tank hatch or the motion of a pump jack. With feedback from the wireless sensor, workers can determine if a tank hatch is ajar and/or a pump jack is idle, and can take immediate corrective action to ensure proper and compliant operations.

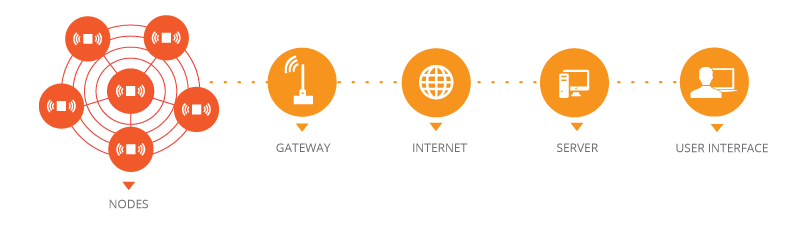

When first introduced to the industry, remote instrumentation was based on wired systems. Today, wireless remote monitoring and control solution systems can simulate the architecture of wired systems using links to transmit data. Offering substantial operating and cost advantages over wired systems, wireless systems are becoming more prevalent in different applications. Here are five reasons why:

-

No Wiring or Trenching

A wired system may require thousands of yards of cable to connect to different endpoints. As installed costs fluctuate from $10 to $20 per foot, a wired system can be expensive if connections are thousands of feet away. Powered by battery, solar, local power, or a power-scavenging device, wireless systems have no conduit requirements, eliminating the need for hardwiring instrumentation.

-

Reduced Installation and Retrofit Cost

While a wired system using 50 to 75 feet of installed conduit can cost as much as $1500, a comparable wireless system can costs just a few hundred dollars per measured point, depending on vendor and application specifications. If repaired or reconfigured, a wired system can require new cables, involving trenching, hardware and labor. A wireless system is easily scaled without adding new hardware. After initial installation, wireless systems can easily add new wireless instruments to meet changing and expanded requirements. In addition, a wireless system can be configured in the shop, reducing on-site labor by 50% to 75%.

-

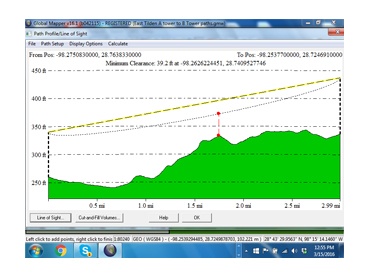

Operate in Different Terrains

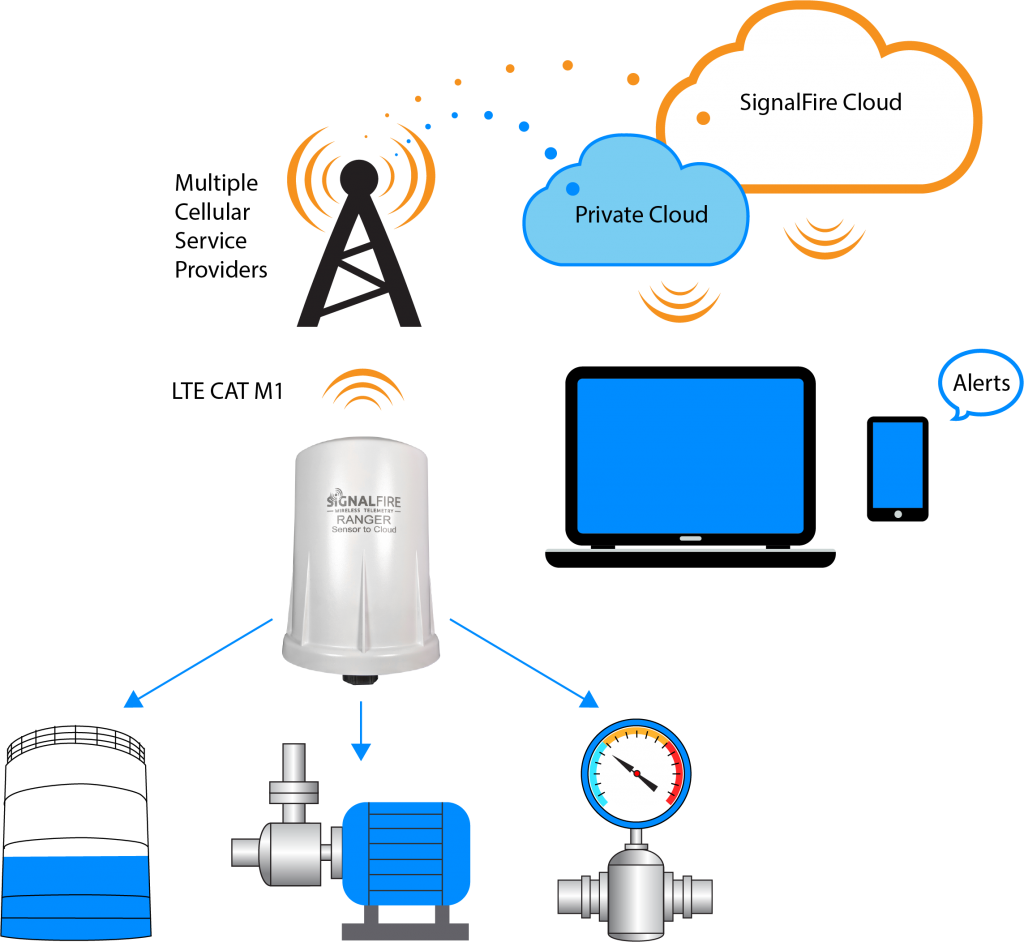

In some cases, wires can’t run on property not owned by the company such as roads, streams or other structures. The industrial transceiver nodes of a wireless remote monitoring system provide powerful, long-range transmission of data in the unlicensed ISM bands that sustains signal strength through terrain, structures, or weather. Even when operating in hostile and dangerous environments, a wireless system can operate unattended for years without being affected by environmental conditions such as snow, rain, dust storms and ice.

-

No Data Loss

Should a wired system fail due to cut wires, corrosion, dirt or another adverse condition, operators are not alerted to the problem, resulting in sub-par operations or failures until instrumentation is back online. Programmed with a communications link alarm, a wireless system provides an alert when data is not in transmission. Most problems are avoidable by preventative maintenance linked to wireless diagnostics.

-

Integrate With Different Sensors

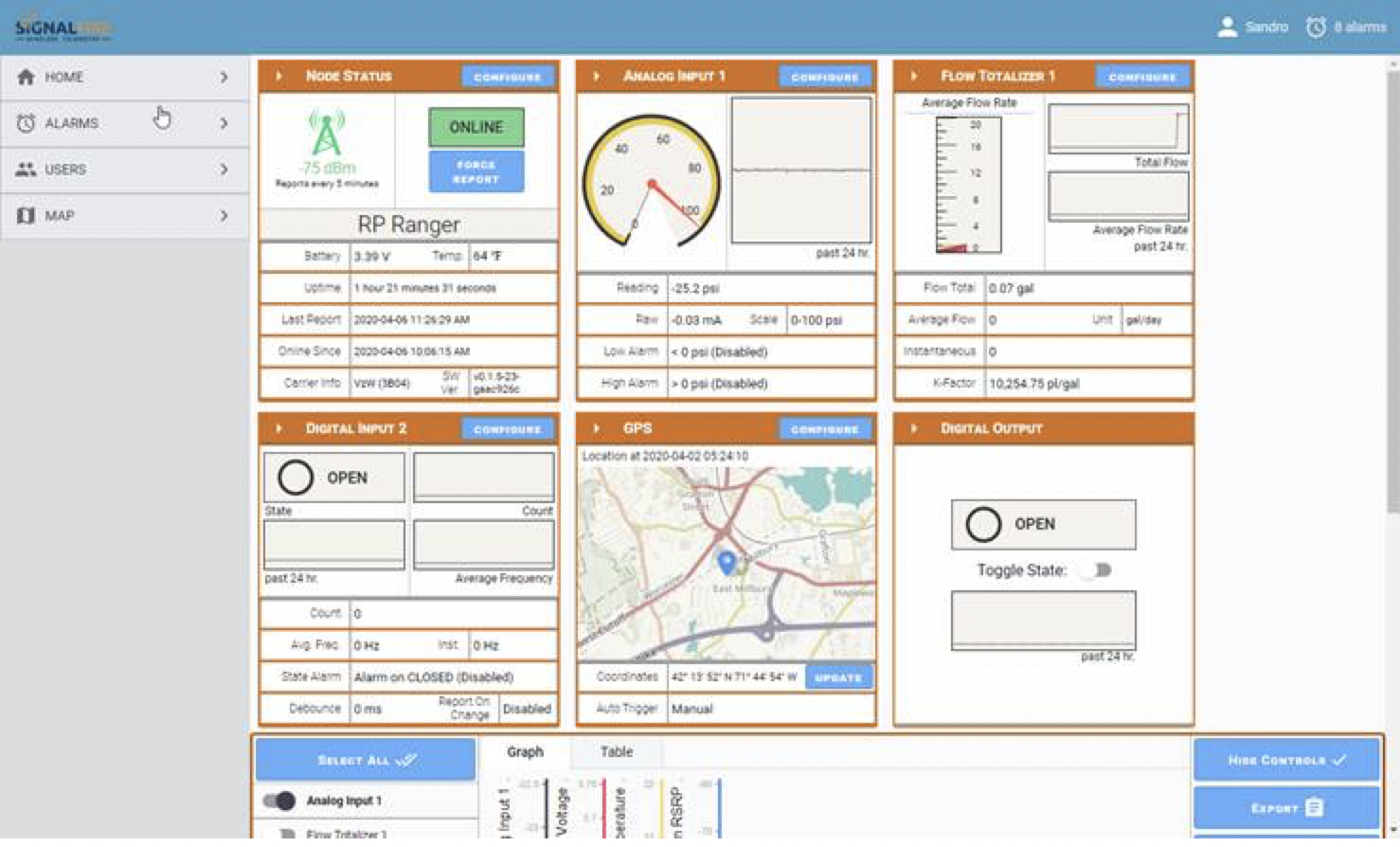

Wireless remote monitoring systems with an open architect allow users to integrate many types of sensors to monitor assets. As a result, a variety of sensors can be added or subtracted as needed to measure parameters such as pressure, temperature, level and flow. Users can choose the best sensor for each application and bring all that data from different sensors to a single point with a single data interface. In addition, robust gateways can accommodate up to 10,000 transceiver nodes, enabling the network to cover a geographic range of hundreds of square miles.

More cost effective and versatile than traditional manual gauges and wired instrumentation, wireless control systems meet different challenges that wired systems just can’t address. Read about the rationale for investing in a wireless tank level system by downloading the article Justifying the Move to Wireless Tank Level Monitoring.