AtTechStar, we believe great measurement starts with the right technology and ends with solutions that are reliable, scalable, and supported long after startup. That’s why we’re excited to expand our analytical portfolio through our representation of Process Insights, bringing together a broad range of proven analytical technologies.

TechStar Expands Analytical Capabilities with Process Insights Solutions

Topics: Analytical Solutions, Analyzer, Process Insights

Seasonal Safety: Best Practices for Fire and Gas Detection Systems

As the year-end holiday season approaches, industrial facilities face unique safety challenges, and strong fire and gas detection systems are critical to maintaining a safe, compliant workplace. A proactive, multi-layered detection strategy not only supports safety during colder temperatures and reduced staffing, it also helps ensure reliable hazard monitoring throughout year-end operations and into the New Year.

Topics: MSA, Gas Detection Solutions, Fixed Gas Solutions, Safety, Flame Detection

Level Measurement in Water & Wastewater: Reliable Data from Inlet to Effluent

In water and wastewater operations, knowing exactly what’s happening inside your tanks, wells, and channels is critical. Level measurement ensures pumps run efficiently, tanks don’t overflow, and solids are processed safely, all while helping you meet strict environmental regulations.

At TechStar, we work alongside operators and engineers to design level measurement systems that deliver dependable performance in the toughest conditions. From clean water tanks to sludge thickeners, we provide solutions built for accuracy, integration, and long-term reliability.

Topics: Level Solutions, Wastewater, water, clarifier level sensor

Optimize Separator Flow with Fox Thermal Thermal Gas Meters

Accurate flow measurement is foundational to operational excellence, especially in separator systems. Whether you’re dealing with gas, water, or multi-phase streams, reliable data drives production performance, environmental compliance, and cost control. That’s why we’re excited to showcase the latest insights from Fox Thermal in the newly released “Separator Application Optimizer.”

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow, Separator

Distributed I/O and Remote I/O Solution Improves Performance and Reliability of Water Treatment Plant

In the evolving landscape of water treatment, operational efficiency and reliability are paramount. The Onondaga County Water Authority (OCWA) in New York serves as a prime example of how modernizing control systems can lead to significant improvements.

Topics: Safety

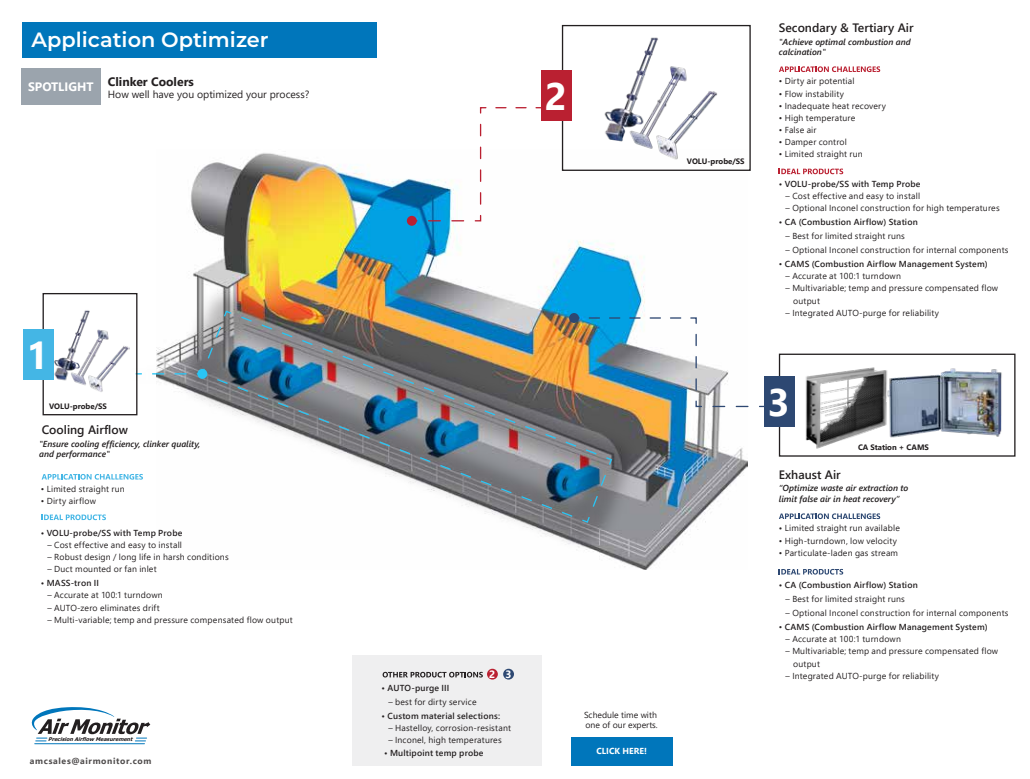

Application Optimizer: Mapping Clinker Cooler Efficiency

We’re excited to announce the release of the new Application Optimizer for Clinker Coolers, a document designed to help cement manufacturers optimize their clinker cooler operations through precise airflow measurement. This Application Optimizer maps out key airflow measurement points across the clinker cooler system, offering actionable insights to improve cooling efficiency, reduce energy consumption, and enhance clinker quality.

Topics: Safety

Tap into the Potential of Self-Checking Gas Sensor Technology

With MSA’s TruCal® technology, available on XCell® hydrogen sulfide (H₂S) and carbon monoxide (CO) gas sensors, you get a smarter, more proactive approach to gas detection. TruCal helps monitor sensor health automatically, so you don’t have to wait until the next scheduled calibration to find out something’s wrong. Whether you’re running critical infrastructure or a high-demand industrial facility, TruCal helps give you added peace of mind, right where it counts: between calibrations.

Topics: MSA, Gas Detection Solutions, Fixed Gas Solutions, Safety

At TechStar, solving process challenges goes beyond instrumentation, it means delivering complete, integrated automation solutions. With years of experience designing and implementing custom systems, our team brings advanced automation to every corner of industry, helping you operate smarter, safer, and more efficiently.

Here’s how different industries are optimizing their operations through custom automation:

Topics: Texas Automation Systems, Automation

A major gas processing plant faced operational inefficiencies due to the need for manual level measurement in their sewage water drain collection pit. The plant required personnel to manually check the pit level and then, depending on the present level in the pit, call a collecting vehicle to drain the sump, leading to delays, inefficiencies, and safety concerns. To enhance automation and remote monitoring, the customer sought a continuous, non-contact radar solution to eliminate human error and improve response time.

Topics: Level Solutions, radar, Magnetrol

Flame detectors are critical for ensuring the safety of personnel, equipment, and operations in facilities where fire hazards exist. However, selecting the right flame detector—and installing it properly—can make a significant difference in the effectiveness of your fire protection system. In this post, we’ll guide you through key considerations when choosing and installing flame detectors to help improve safety at your facility.

Topics: MSA, Safety, Flame Detection