As the year-end holiday season approaches, industrial facilities face unique safety challenges, and strong fire and gas detection systems are critical to maintaining a safe, compliant workplace. A proactive, multi-layered detection strategy not only supports safety during colder temperatures and reduced staffing, it also helps ensure reliable hazard monitoring throughout year-end operations and into the New Year.

Seasonal Safety: Best Practices for Fire and Gas Detection Systems

Topics: MSA, Gas Detection Solutions, Fixed Gas Solutions, Safety, Flame Detection

Distributed I/O and Remote I/O Solution Improves Performance and Reliability of Water Treatment Plant

In the evolving landscape of water treatment, operational efficiency and reliability are paramount. The Onondaga County Water Authority (OCWA) in New York serves as a prime example of how modernizing control systems can lead to significant improvements.

Topics: Safety

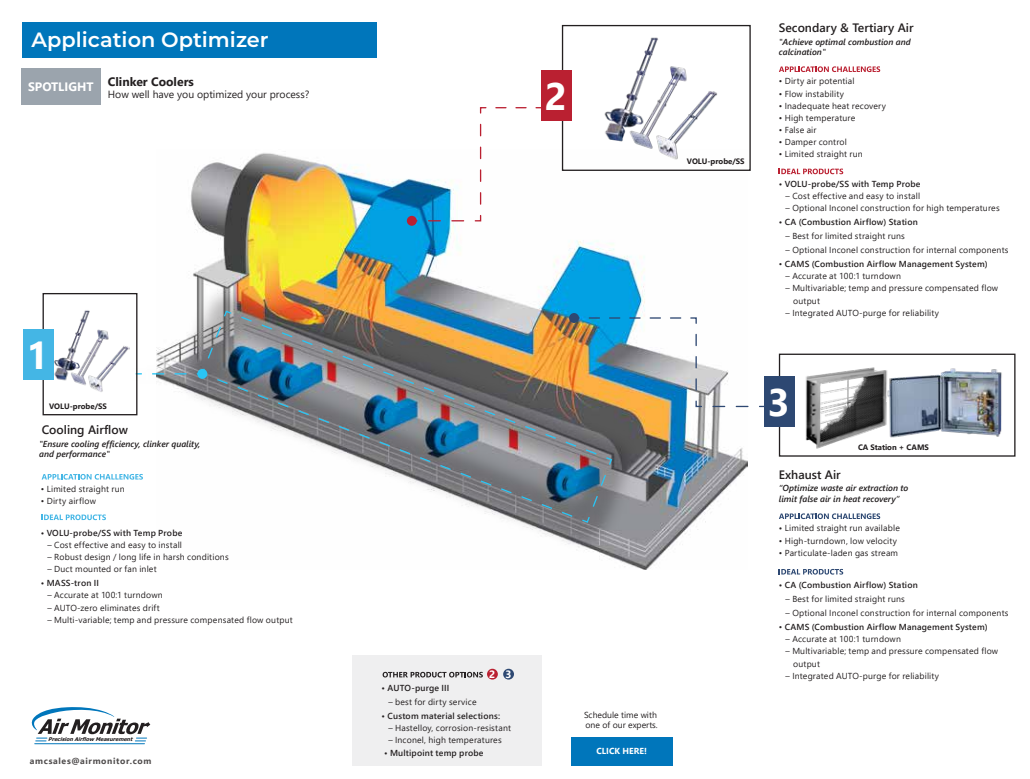

Application Optimizer: Mapping Clinker Cooler Efficiency

We’re excited to announce the release of the new Application Optimizer for Clinker Coolers, a document designed to help cement manufacturers optimize their clinker cooler operations through precise airflow measurement. This Application Optimizer maps out key airflow measurement points across the clinker cooler system, offering actionable insights to improve cooling efficiency, reduce energy consumption, and enhance clinker quality.

Topics: Safety

Tap into the Potential of Self-Checking Gas Sensor Technology

With MSA’s TruCal® technology, available on XCell® hydrogen sulfide (H₂S) and carbon monoxide (CO) gas sensors, you get a smarter, more proactive approach to gas detection. TruCal helps monitor sensor health automatically, so you don’t have to wait until the next scheduled calibration to find out something’s wrong. Whether you’re running critical infrastructure or a high-demand industrial facility, TruCal helps give you added peace of mind, right where it counts: between calibrations.

Topics: MSA, Gas Detection Solutions, Fixed Gas Solutions, Safety

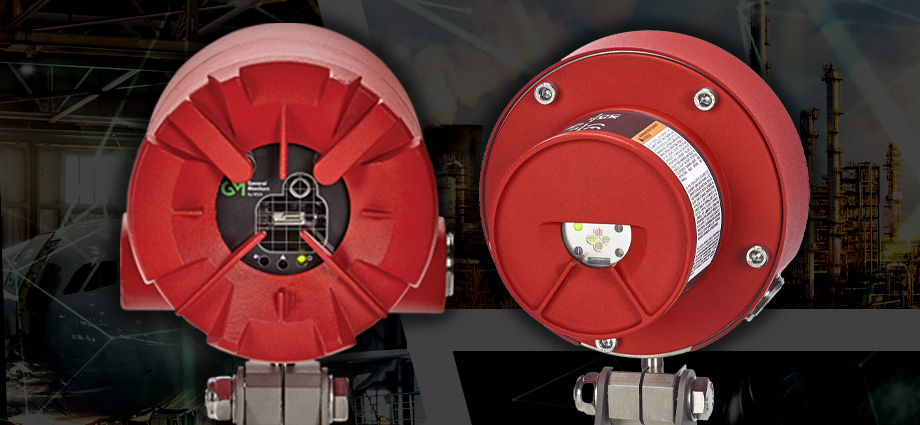

Flame detectors are critical for ensuring the safety of personnel, equipment, and operations in facilities where fire hazards exist. However, selecting the right flame detector—and installing it properly—can make a significant difference in the effectiveness of your fire protection system. In this post, we’ll guide you through key considerations when choosing and installing flame detectors to help improve safety at your facility.

Topics: MSA, Safety, Flame Detection

As a safety professional, selecting flame detectors that align with your facility’s requirements is essential. Discover the key factors to consider when choosing a flame detection system.

Topics: MSA, Safety, Flame Detection

How Advanced Technologies Minimize False Alarms in Flame Detectors

In industrial settings where flammable materials are handled, flame detection systems are an important layer of safety programs. False alarms in these systems disrupt operations and can risk desensitizing personnel to alerts. Different flame detection methods have different false alarm profiles in different applications. Advanced flame diagnostic technologies have been and are being developed to enhance these systems, including to reduce false alarms. Among these technologies, artificial neural networks (ANNs) stand out as a promising option, offering false alarm reduction.

Topics: MSA, Safety, Flame Detection

The potential dangers associated with ammonia gas leaks necessitate a thorough understanding of the risks and implementation of stringent safety measures. Ammonia is a commonly used industrial chemical, serving various purposes across different sectors. The potential dangers associated with ammonia gas leaks necessitate a thorough understanding of the risks and implementation of stringent safety measures. In this post, we explore the general dangers of ammonia gas leaks and critical safety precautions to help protect people, property, and the environment.

Topics: MSA, Gas Detection Solutions, General Monitors, Fixed Gas Solutions, Safety, Flare Gas

Condition Monitoring is a necessity in all process industries. Our monitoring solutions for safety, condition and performance monitoring of rotating machinery in many applications in industries such as steel, mining, cement, pulp and paper, maritime and other industries:

Topics: Safety, vibration, Condition Monitoring, BK Vibro

The Importance of Calibrating Fixed Gas Detectors for Safety

Fixed gas detectors play a critical role in safeguarding people, places, and the planet against potentially life-threatening gases in environments ranging from high value industrial complexes to laboratories and hazardous confined spaces. However, to ensure their accuracy and reliability, regular calibration is an indispensable practice.

Calibration is usually a two-step procedure – the zero and the span. In the first step, the sensor is zeroed using ambient air after confirming that the target gas is not present or by using a suitable gas from a cylinder. The second step is to expose the instrument to the calibration gas that contains a known concentration of the target gas the sensor is designed to measure. The readings are then adjusted to match these values.

Topics: MSA, X5000, Gas Detection Solutions, Fixed Gas Solutions, Safety, Field Service