Vortex flowmeters are highly versatile devices that can measure the flow of liquids, gases, and steam across a wide range of temperatures and pressures. Their unique advantages make them particularly well-suited for measuring steam flow, offering benefits over other types of flowmeters.

Vortex Flowmeters: The Ideal Solution for Steam Flow Measurement

Topics: Yokogawa, Flow Meter Solutions, Flow Solutions, flow

YNOW2024: Impact Your World will showcase best practices, methodologies, and emerging digital technologies from end users, Yokogawa, KBC (A Yokogawa Company) and our partners.

Topics: Yokogawa

Flowmeters play a critical role in today’s process world. As technology has advanced through the decades, a variety of flowmeter technologies has expanded the ways, customers, control and monitor their utilities, steam, fiscal metering, etc. Today, a few of the top flowmeters on the market are the Coriolis, magnetic, vortex, ultrasonic, differential pressure, and variable area meters. Several other technologies, such as turbine, thermal mass, and positive displacement, are also available. Since each flowmeter has positive and negative attributes, careful consideration is required to avoid purchasing a technology that is inappropriate to the application.

Topics: Yokogawa, Flow Meter Solutions, Flow Solutions, flow

Temperature is one of the four basic process measurements (others being Pressure, Level, and Flow). Temperature measurements are used in an array of different applications. The inaccuracy of a temperature reading can have an impact on the bottom line.

Topics: Yokogawa, Temperature Solutions

Controlling the world’s water resources is arguably one of the most critical issues. Water demand from industry and domestic users is set to rise throughout the industrialized world, while water supplies are finite. Legislation constantly demands improvements in potable water quality and reduces the contaminants that may be discharged. Wastewater treatment is one way to get water back. Wastewater is subjected to various treatments in wastewater treatment plants, each intended to remove contaminants and other hazardous substances from the water. The objective is to create water from sewage that is safe to discharge into waterways and won’t endanger the environment or human health. Over the last few years, Yokogawa has been applying minimized maintenance measurement systems to an industry that, more than ever, is concerned with condition-based maintenance and the integrity of the measured variable.

Topics: Yokogawa, Analytical Solutions, Wastewater, Analyzer

Ski resorts in North America depend on snowfall for enthusiasts to enjoy winter sports such as skiing and snowboarding. However, when nature does not cooperate, artificial snow is required to maintain the base level. Artificial snow consists of small particles of ice that are used to increase the snowpack. It is produced by a machine that uses a high-pressure pump to spray a mist of water into the cold air. The water droplets crystallize to form artificial snow.

Topics: Yokogawa, Flow Meter Solutions, flow

Plant managers are continuous on the lookout for ways to improve the productivity and efficiency of plant processes. There is a growing need for solutions that simplify the collection of data from equipment. Yokogawa realized this demand in the process industry. Hence in 2019, the Sushi Sensor – a compact, wireless sensor for measuring vibration and temperature – was launched. This smart sensor is also optimized for Industrial IoT applications (IIoT). But what makes the Sushi Sensor special? For which assets are they applicable to and how does it realize preventive maintenance? In this blog, we’re going to answer 7 frequently asked questions about the Sushi Sensor.

Topics: Yokogawa, Wireless Sensor, vibration, Condition Monitoring, Temperature Solutions, Pressure Solutions, Sushi Sensor

DPharp digital sensor uses two single crystal silicon resonators vibrating at their natural frequencies. When pressure is applied, one of the resonators goes into tension, while the other goes into compression mode. The CPU directly counts the sensor output frequencies without any additional A/D conversion. Due to the excellent elastic properties of silicon material, the DPharp sensor exhibits greater linearity and repeatability, with no inherent hysteresis. Resonant sensor also provides a large output signal resulting in greater sensitivity and higher turndown.

Topics: Yokogawa, Differential Pressure, Pressure Solutions

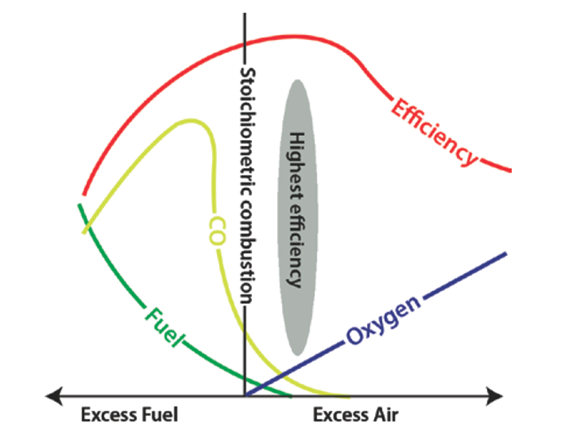

Optimizing Boiler Efficiency | Increase Your Bottom Line

Optimizing boiler efficiency will increase your bottom line. Did you know that every 10% excess oxygen results in 1% in wasted fuel? With that in mind, Yokogawa Zirconia Oxygen analyzers have a 50-year proven success record for providing:

Topics: Yokogawa, Analytical Solutions, Analyzer

Written By TechStar Solution Specialist, Josh Longcor

It is safe to say that everyone’s goal in process control is to increase reliability of their process measurements. Facilities spend endless resources to identify and displace problematic points, also know as “bad actors”. One common problem area in a refinery is reliably measuring the heavy residual hydrocarbons from the “bottoms” of the distillation towers in the crude unit. Typically, these applications are Vaccum Distillation (VDU) Feed & Delayed Coker (DCU) Feed; also known as crude furnace pass flows.

Topics: Yokogawa, Ultrasonic Flow, flow

.png)