Part of the Moore Industries FS Functional Safety Series, the exida-certified SIL2/3 capable SLA is a versatile multiloop and multifunctional Logic Solver and Alarm that acts on hazardous process conditions, warns of unwanted process parameters, performs on/off control, and provides emergency shutdown in Safety Instrumented Systems (SIS) and traditional alarm trip applications.

5 Reasons Why the SLA is Your Single or Multi-Loop Logic Solver Choice

Topics: Moore Industries, Signal Conditioning and Isolation Solutions

Case Study: Wireless Solution & Process Automation Scales Plant Operations

TechStar is proud to represent and distribute for industry-leader Moore Industries.

As part of this case study, wireless network solutions were pre-configured and provided by Moore Industries as part of an all-inclusive solution for a pulp and paper plant to automate dated manual processes, display digital and analog signal readouts, and archive historical data to meet compliance regulations.

This blog was originally posted by Moore Industries and authored by Jim McConahay

- A major pulp and paper company had a dated, inefficient process for monitoring and recording daily effluent water rates.

- A necessary task in order to maintain state regulations, the company needed help optimizing this process to save time, balance employee workload, and help scale company operations.

- Through Moore Industries’ system analysis and installation upgrade, the plant easily met all of these needs while also reducing operating costs and saving time.

Case Study Summary

In order to maintain compliance with state regulations, a major pulp and paper company was required to continuously monitor and record daily effluent water rates at their plant.

Fulfillment of this task was met by sending an employee from their main control site to a remotely located pond three times a day to manually record water levels—the process was inefficient, time-consuming and didn’t provide them with real-time data.

Frustrated by the lack of accurate results, inefficiency of their current process and added employee workload, the paper plant reached out to Moore Industries for a modern process solution.

Upon analysis of their existing systems, an installation and upgrade was performed which allowed them to digitally and wirelessly monitor their water levels.

Topics: Moore Industries, digital and wireless technology, autoline controls, plant operations, process automation

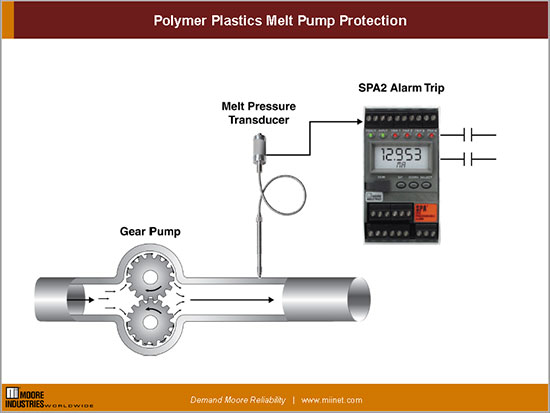

Melt pumps used in polymer production are a special high temp positive displacement pump used at the discharge of an extruder to assure a smooth, high temperature and high pressure (often several thousand psi) supply of the polymer to the filter screen and die for better throughput and uniformity of product. Blockage of the filter screen or die can cause spikes in pressure high enough that the die can be damaged or blown off the feed tap. When that happens, the released polymer will cool and harden at ambient pressure and temperature, requiring hours of cleanup. Downtime costs can be significant.

Topics: Moore Industries, Signal Conditioning and Isolation Solutions

Industrial compressors are often used in large chemical plants to supply headers with air for pneumatic instruments and valves. These compressors have to run at precise speeds. If they start to run too fast they can become very dangerous and expensive to repair.

Topics: Moore Industries, Temperature Solutions

Moore Industries’ Digital and Wireless Technology Reduces Legwork at Pulp and Paper Site

This blog was originally posted by Moore Industries.

State regulations required a major pulp and paper company to monitor and record daily effluent water rates. This requirement was being fulfilled by sending an employee from their main control site to a remotely located pond three times a day to manually record water levels. This process was inefficient, time-consuming and didn’t provide them with real-time data.

Topics: Moore Industries

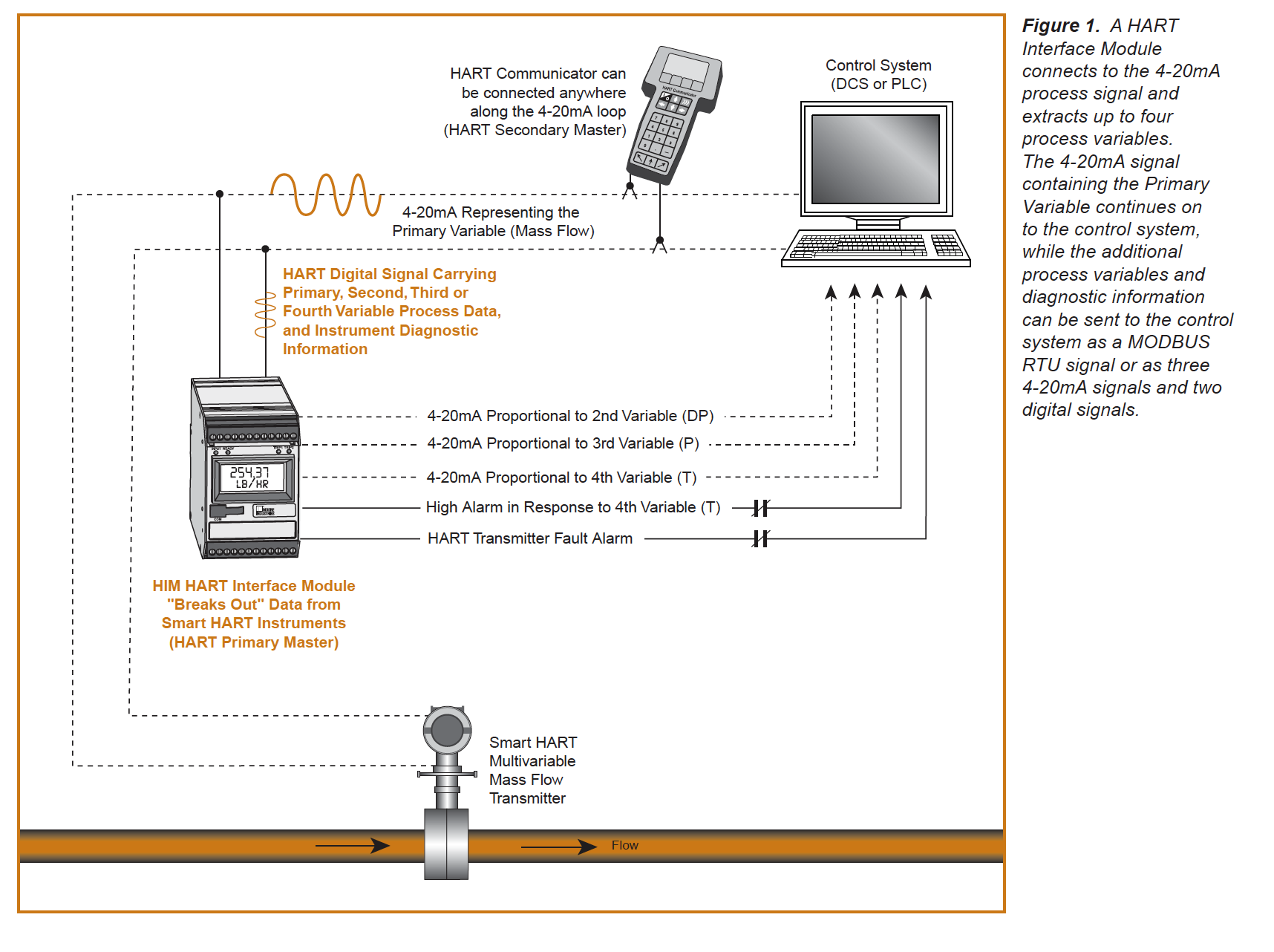

According to the HART® Communications Foundation, there are more than 30 million HART-enabled instruments installed in chemical and process plants worldwide, and nearly most process transmitters made today are HART compatible.

Topics: Moore Industries

Bridging the Gap between HART Devices and IIoT, the Industrial Internet of Things

One smart instrument communication protocol has outlasted and outsold all of the alternative digital instruments and protocols introduced to market over the last thirty years -- HART and the devices that use it. With over 40 million installed HART devices worldwide, HART is not only here to stay but unlike other protocols, it also continues to get updated revisions that enhance data exchange capacity, speed, number of devices on a network, support over Ethernet, and wireless capability.

Topics: Moore Industries

Accelerate Your HART Data at the Speed of Ethernet With the New HES HART to Ethernet Gateway

Blog originally posted by Moore Industries.

Timely knowledge about your process enables better decisions and faster preventive action. Now you can get the process detail that you need from your Smart HART devices to MODBUS/TCP and HART-IP based monitoring and control systems at the speed of Ethernet with the HES HART to Ethernet Gateway System from Moore Industries.

Topics: Moore Industries

Originally posted by Moore Industries.

The original goal when creating the WORM Flexible Temperature Sensor was to provide a sensor that could be cut in the field to accommodate various size wells and assemblies. Experience has proven this design helps with other obstacles in the field:

Topics: Moore Industries

When You Need to Pass HART Data, Get a Little Super Hero.

This blog was originally posted by Moore Industries.

HART® Isolators from Moore Industries

HART® data is extremely useful but when you have to isolate your loops in order to share key process signals or keep your systems safe from power issues, HART data can be stripped off and blocked by most isolators. This prevents your critical HART data from reaching your to asset management systems, programming devices or host systems.

HART Isolators from Moore Industries can save the day. With built-in HART pass-through technology you can rest assured that when your loops use HART transmitters, critical and valuable HART diagnostic, process, and calibration information can be read on either side of the Moore Industries HART Isolators.

Topics: Moore Industries

.png)