In the pulp and paper industry, emissions of hazardous gas caused by chemical reactions during pulp production can pose a dangerous operating environment. To ensure the highest safety standards for employees while meeting industry environmental regulations, paper mills must continuously monitor levels of gases such as hydrogen sulfide (H2S) within different areas of the facility to ensure they remain within limit values.

Application:

A paper plant needed to replace a hard-wired gas monitoring system used for tracking and reporting H2S levels as its old wiring and an open circuitry

no longer worked reliably. Plus, the plant needed

to replace older gas level detection sensors. When looking to update and expand its gas monitoring system, the plant found that a wireless sensor control solution offered a more cost-effective option for replacing its former hard-wired system.

PRODUCT SUPPLIED:

-

Sentinel HART Nodes

-

Gateway Stick: Integrated gateway and high-gain antenna

-

MSA Ultima X5000 Gas Level Detection Sensors that communicate via HART

CHALLENGE:

The plant needed to replace obsolete H2S sensors with newer versions throughout the plant while adding new monitoring points. As the total installation cost of running hardwired signals to all of the areas of facility proved expensive, the plant sought a wireless solution.

SOLUTION:

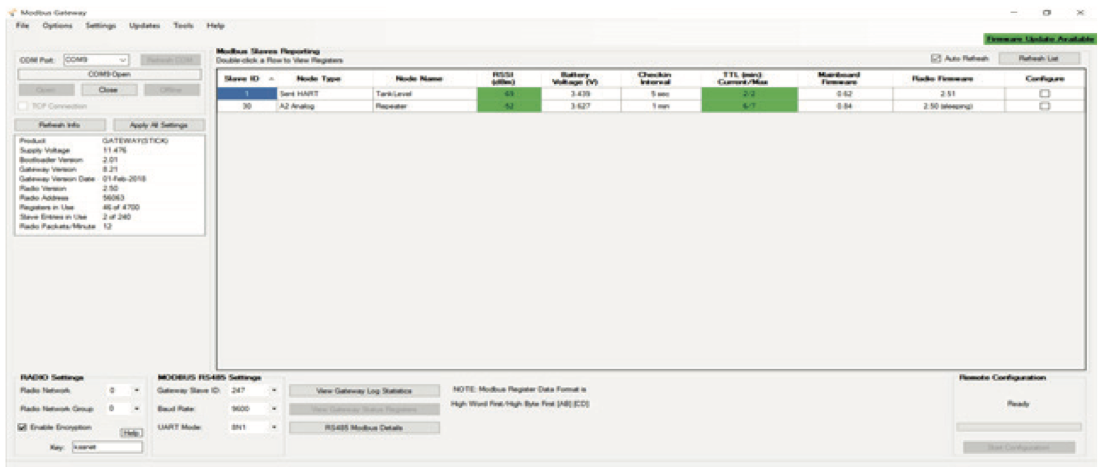

A SignalFire Wireless Sensor Control System composed of Sentinel nodes and a Gateway Stick provides sensor data for download into a control system that immediately alerts technicians when H2S is detected within the paper plant. Wired to MSA gas detectors, the SignalFire HART Sentinel nodes wirelessly communicate sensor data over a 900 MHz FHSS Wireless Network to a Gateway Stick where data is stored within Modbus registers. The Modbus data is available to control systems (PLC & DCS) for operator monitoring, alarm indication, trending and report generation for historians.

Also, this system provides remote sensor calibration and configuration via HART communications and PACTware. The previous hard-wired gas monitoring system did not integrate into a control system,

thus not providing alarm, trending and reporting capabilities.

The 900 MHz transmission of the wireless telemetry system works better in areas where metal is present and communicates further distances compared to 2.4GHz competitive systems.

The Gateway Stick – that includes an integrated gateway and high-gain antenna in a simple, mountable package – is positioned at the highest point of the plant and wired to an Ethernet switch to communicate back to the DCS and/or PLC.

Sentinel nodes are configured to check-in periodically with the gas level detectors. Sensors are powered

by a 24VDC source, which allows all nodes to act as repeaters providing enhanced wireless coverage of the entire plant. A long-range repeater node added to a section of the plant boosts signal strength by repeating messages from nodes to the Gateway.

The above shows the signal strength for the site survey. The paper plant is very impressed with the signal strength and breadth of product communications. They stated that they would have to install two competitive wireless systems to achieve the same capabilities of the SignalFire telemetry system.