Measuring Water Vapor in Hydrocarbon Streams

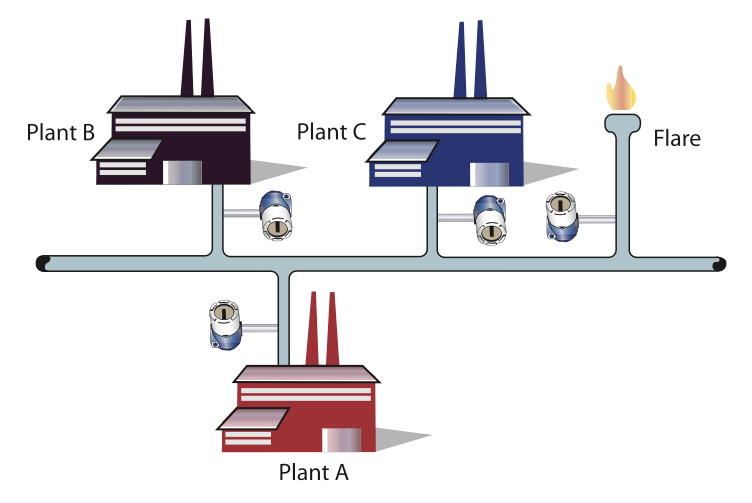

Extracted from a variety of different sources, natural gas is composed of many different hydrocarbons and includes other, less desirable, impurities. These impurities – such as water, carbon dioxide, and hydrogen sulfide – are removed due to adverse effects, including:

- Reducing the heating value of the natural gas

- Damaging piping and other mechanical hardware due to freezing or corrosion

- Meeting tariff limits associated with transaction contracts