For industries such as steel, mining, cement, pulp and paper, maritime and others, our monitoring solutions for rotating machinery are in use in many applications around the world. They all require dedicated monitoring solutions and strategies:

TechStar

Recent Posts

Condition & Vibration Monitoring Solutions For The General Industry

Topics: vibration, Condition Monitoring, BK Vibro

Today, terabytes of signal data are being generated from sensors embedded in industrial equipment. The capability to handle such large streams of data and draw actionable conclusions from is a task that requires artificial intelligence.

Topics: vibration, Condition Monitoring, SKF

TECHSTAR FLEX | ONE-TOOL SOLUTION FOR PROCESS COMMUNICATION

Introducing the TechStar FLEX – the latest in HART Communicators! While not the first on the market, the FLEX is the more cost-effective and FLEXible option available, providing a one-tool solution for your programming, troubleshooting and HART maintenance needs. Benefits of the TechStar Flex include:

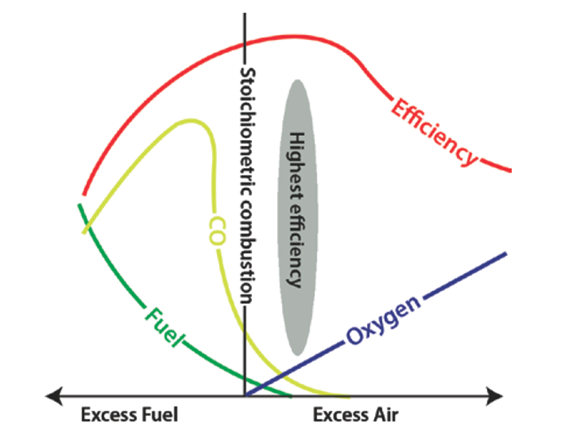

Optimizing Boiler Efficiency | Increase Your Bottom Line

Optimizing boiler efficiency will increase your bottom line. Did you know that every 10% excess oxygen results in 1% in wasted fuel? With that in mind, Yokogawa Zirconia Oxygen analyzers have a 50-year proven success record for providing:

Topics: Yokogawa, Analytical Solutions, Analyzer

Common Results of Gas Uses in Industrial Processes

There are three key results of measuring the flow of air or gases with industrial gas flow meters in industrial applications:

- efficiency improvement

- leak reduction

- increased product quality

Topics: Fixed Gas Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, flow

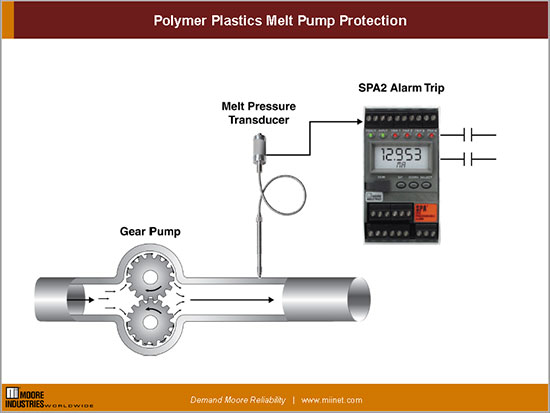

Melt pumps used in polymer production are a special high temp positive displacement pump used at the discharge of an extruder to assure a smooth, high temperature and high pressure (often several thousand psi) supply of the polymer to the filter screen and die for better throughput and uniformity of product. Blockage of the filter screen or die can cause spikes in pressure high enough that the die can be damaged or blown off the feed tap. When that happens, the released polymer will cool and harden at ambient pressure and temperature, requiring hours of cleanup. Downtime costs can be significant.

Topics: Moore Industries, Signal Conditioning and Isolation Solutions

Meeting the Challenge of Portable Moisture Measurements

If you’re a user of moisture analyzers, you’ve probably experienced challenges in performing a quick, accurate measurement using a portable instrument. Portable moisture analyzers are typically used to verify the moisture reading of a fixed-installation instrument or to conduct spot-sampling measurements at remote sites which lack a permanently installed device. In my experience performing portable measurements, I’ve seen several common obstacles a user may encounter:

Topics: Moisture Measurement Solutions, AMETEK Process Instruments

Optimize Your Process: Innovative Solutions In One Click

Our instrumentation & analytical solutions are critical to the day-to-day operation and overall success of your process. Understanding that downtime is simply not an option, we have a new system in place to ensure your process is prepared for the unexpected. Introducing TechStar One Click, our new eCommerce purchasing option.

Topics: Level Solutions, Signal Conditioning and Isolation Solutions, Wireless and Telemetry Solutions, Pressure Solutions, Upstream Solutions, Flow Solutions, TechStar One Click

Application Spotlight: Wireless Monitoring of Hydroelectric Dam Levels

APPLICATION:

Hydroelectric dams and their reservoirs store a significant amount of energy, which can be fed into the grid very quickly, when necessary. In determining the amount of available energy, the water level height at the reservoir must be monitored accurately by a reliable monitoring system.

PRODUCT SUPPLIED:

SignalFire Remote Sensing System™ (SRFSS)

Topics: Signal Fire, Wireless and Telemetry Solutions, water

4 Reasons Thermal Mass Flow Meters Make Sense in Pharmaceutical

Excessive gas consumption wastes money - and of greater importance - can affect product quality and safety. The pharmaceutical industry uses large quantities of nitrogen, oxygen, carbon dioxide gas, and air. Without good air and gas flow measurement, cost, quality, and consumer safety will suffer.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Pharmaceutical