Accurate flow measurement is foundational to operational excellence, especially in separator systems. Whether you’re dealing with gas, water, or multi-phase streams, reliable data drives production performance, environmental compliance, and cost control. That’s why we’re excited to showcase the latest insights from Fox Thermal in the newly released “Separator Application Optimizer.”

Optimize Separator Flow with Fox Thermal Thermal Gas Meters

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow, Separator

The US Environmental Protection Agency (EPA) 40 CFR Part 60 Subpart OOOO, or Quad O, is a federal regulation under the Clean Air Act for reducing harmful air quality emissions from oil and gas facilities.

The EPA issued a final rule effective May 7, 2024, containing new source performance standards (NSPS) regulating greenhouse gases (GHGs) and volatile organic compound (VOC) emissions for the oil and gas industry. It also finalized guidelines for states to follow in developing their emission reduction standards for limiting fugitive emissions from existing sources.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

Is the Equipment or Process you Manage Affected by Quad-O?

What is “Quad-O”?

The US Environmental Protection Agency (EPA) 40 CFR Part 60 Subpart OOOO is colloquially known as “Quad-O”. It is a regulation under the Clean Air Act meant to identify emissions sources in oil and natural gas operations contributing to pollution and reduce emissions. The emissions of methane and VOCs from oil and gas equipment used in the production and processing and the transmission and storage of natural gas are affected.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

Hydrogen and Hydrogen Blend Use Are on the Rise in the Industrial and Energy Sectors

Although there are many different hydrogen production types including black, pink, turquoise, and yellow, the most common type is from “grey” sources (95%). The steam/methane reforming process is used to convert natural gas or methane into hydrogen. A pollutant by-product of this process is CO2.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Hydrocarbon, flow

Flare gas stacks and combustors are used in many industries including oil & gas, industrial, biogas, and wastewater treatment. These systems are important for burning waste gases produced during operations such as drilling, chemical processing, or biogas reclamation.

In some locations, drilling for oil or natural gas releases hydrocarbon gases that can’t be captured and used, so a gas flare or combustor is needed to relieve excess pressure in the system. Flaring is also used during construction, testing, and maintenance of newly drilled wells or fracking sites.

Digesters used in landfills or wastewater facilities break down waste and produce methane and carbon dioxide, two greenhouse gases (GHGs) that are typically flared, collected for use as a fuel gas in equipment used at the facility, or stored for sale. Flares burn the biogas or waste gases to minimize harmful GHG emissions when flaring becomes necessary due to pressure release events.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

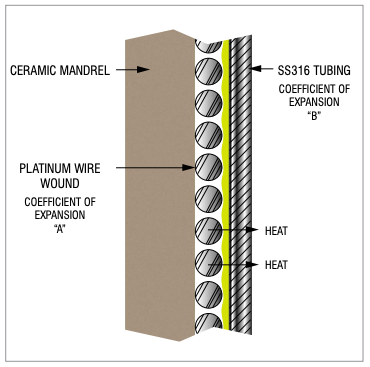

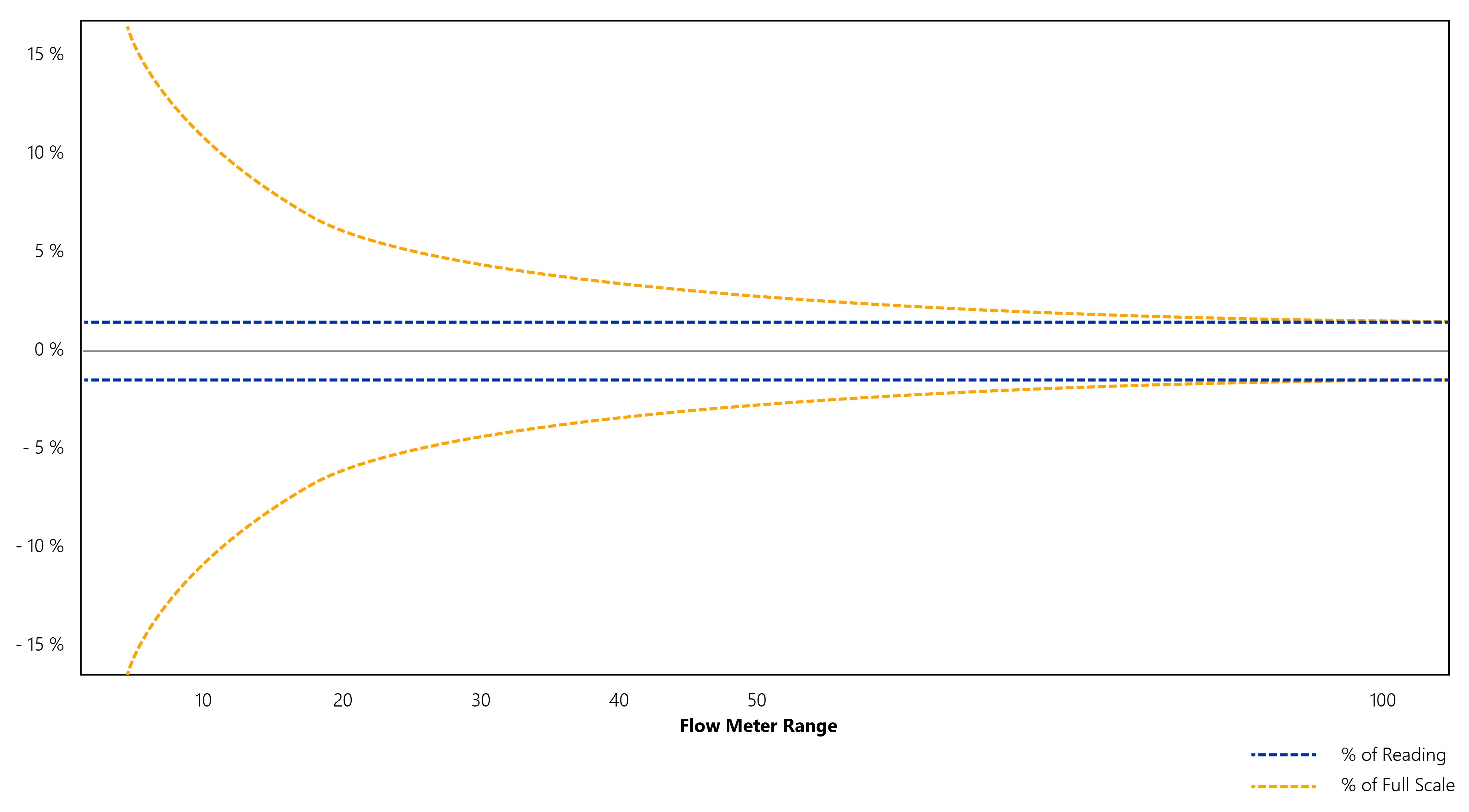

Advantages of Sensor Technology: Accuracy and Meter Calibration

The accuracy of a thermal mass flow meter is dependent upon the technology type and the quality of the materials used for the meter’s sensor design. A well-designed sensor is made to measure flow accurately over a long period of time with minimal drift, independent of recalibration and calibration validation diagnostics. For a thermal mass flow meter, the materials used in the manufacture of the sensor play a vital role in the overall performance of the sensor. The materials must create the best environment for heat transfer - the essential principle of thermal mass flow measurement - or the accuracy and response time suffer.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

What is Flow Rate and Why is It Important in Process Applications?

In an industrial setting, controlling processes with accurate data is an essential part of keeping the process running smoothly. Control systems are equipped with instrumentation like thermal flow meters to feed flow data like gas temperature and gas flow rate into the system. So, what is flow rate and why is it important? The flow rate of the gas tells the system how much of a gas is flowing through a cross section of a pipe at a prescribed unit of time. Flow rate data can help with many things, including the following:

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

Common Results of Gas Uses in Industrial Processes

There are three key results of measuring the flow of air or gases with industrial gas flow meters in industrial applications:

- efficiency improvement

- leak reduction

- increased product quality

Topics: Fixed Gas Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, flow

4 Reasons Thermal Mass Flow Meters Make Sense in Pharmaceutical

Excessive gas consumption wastes money - and of greater importance - can affect product quality and safety. The pharmaceutical industry uses large quantities of nitrogen, oxygen, carbon dioxide gas, and air. Without good air and gas flow measurement, cost, quality, and consumer safety will suffer.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Pharmaceutical

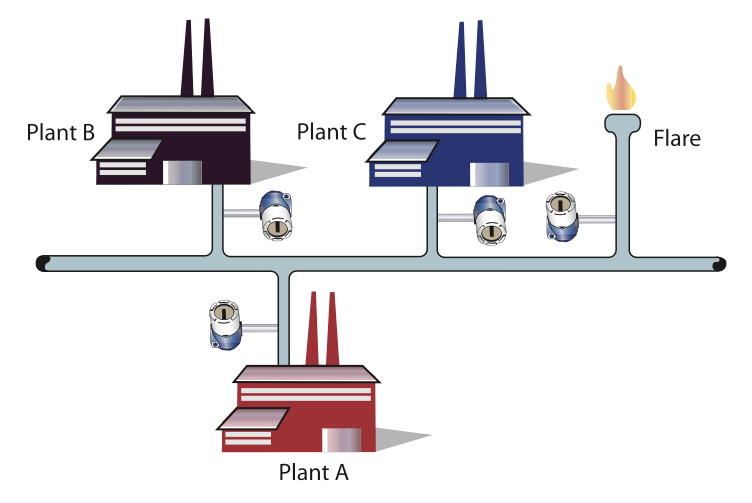

Direct Mass Measurement of Flare & Combustor Gas Flow Rates

Providing exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

Flare stacks and combustors are used to burn waste gases from the plant, converting chemical and organic hydrocarbons into primarily water vapor and CO2. Some processes also use relief valves to vent flammable gases to the flare stack during upset conditions.

Applications include oil and gas well drilling operations, oil refineries, chemical process plants, gas distribution infrastructure, and landfills. Flares are subject to stringent regulations, requiring operators to measure, record and report the amount of flared gases.

Due to the potential for large changes in flow rates, density, pressure and gas composition, flare gas measurement is one of the most difficult and demanding flow applications. Fox Thermal flow meters have demonstrated their ability to measure the low-flow rates typical of normal flare conditions, and also the high velocities found in upset conditions.

Fluid composition and installation anomalies can also affect flow meter performance. Fox Thermal's calibration lab employs a wide range of gases, gas mixtures, temperatures, pressures and line sizes to simulate actual fluid and process conditions. This real-world approach improves installed accuracy and minimizes measurement uncertainty.

Fox Flow Meter Advantages in Emissions Monitoring Applications

-

Exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

-

Stainless steel sensor is suitable for corrosive, particulate-laden gas streams

-

No temperature and pressure compensation required

-

Direct mass flow measurement

-

Built-in alarms, totalizers and a wide variety of communications protocols available for easy interfacing with emissions management systems

-

Oil and Gas Well Drilling Operations (On and Off shore)

-

Oil Refineries

-

Chemical/Petrochemical Processing Plants

-

Gas Distribution Infrastructure

-

Landfills

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, Flare Gas