What is “Quad-O”?

The US Environmental Protection Agency (EPA) 40 CFR Part 60 Subpart OOOO is colloquially known as “Quad-O”. It is a regulation under the Clean Air Act meant to identify emissions sources in oil and natural gas operations contributing to pollution and reduce emissions. The emissions of methane and VOCs from oil and gas equipment used in the production and processing and the transmission and storage of natural gas are affected.

Quad-O is receiving more attention due to recent changes to the rule under OOOOb and OOOOc. Let’s get a closer look at what processes are affected followed by a look at the evolution of the rule since its inception in 2012.

Where do the EPA’s Quad-O Rules Apply?

In the image above, various equipment and processes are labeled to correspond to the numbers below.

In production and processing, the EPA’s methane rule applies to equipment and processes at:

- Onshore well sites

- Storage tank batteries

- Gathering & Boosting compressor stations

- Natural gas processing plants

In natural gas transmission & storage, the EPA’s methane rule applies to equipment and processes at:

- Compressor stations

- Storage tank batteries

Crude oil to petroleum refineries are covered by separate EPA rules. Distribution is also not covered by Quad-O. We’ll go into more details on applicable equipment in the section labeled “Rules Application Details by Site” below.

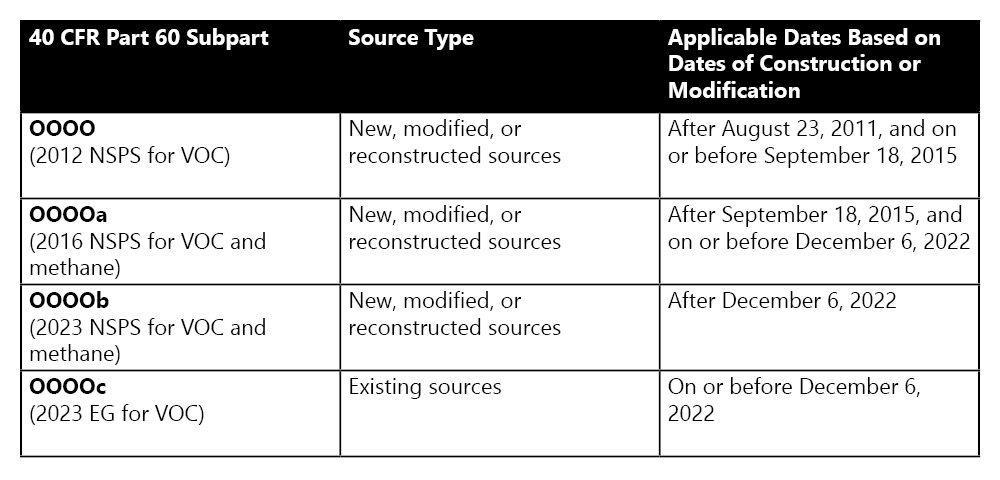

Evolution of Quad-O: Applicability Dates for Subpart Rules

After Quad-O was first enacted in 2012, it was expanded in 2016 to cover methane and to incorporate other equipment or processes that were not in the initial regulation. That rule became OOOOa and continued to affect source types that were new, modified, or reconstructed. More recently, Quad-O has been expanded through NSPS OOOOb to include more equipment from new, modified, or reconstructed sources along with EG OOOOc for the establishment of state Emissions Guidelines (EG) and compliance schedules for the control of greenhouse gas (GHG) emissions from existing sources. The table below summarizes the initial regulation and the three subsequent expansions of the rule.

The applicable dates in the table are important as they determine how affected source types will be labeled (new, existing, etc) upon implementation of the rule. Until recently, the NSPS for OOOO and OOOOa only affected new, modified, or reconstructed sources. After the more recent plan’s implementation, existing sources will be subject to EG OOOOc. Affected facilities will need to comply no later than 60 days after the publication of the rule in the federal register or upon initial startup, whichever date is later. The rules were published in the Federal Register on March 8, 2024, after being announced on December 2, 2023. The effective date of these rules was May 7, 2024.

Notable Changes Under OOOOb

Routine flaring of associated gas from new oil wells will be phased out over two years under OOOOb. By March 8, 2026, gas must be routed to a sales line, used on-site, or used for some other beneficial purpose (with reasonable exemptions for certain temporary and emergency uses of flaring). This will promote the use of closed-loop and green completions to reduce waste and emissions.

OOOOb imposes a limit on vent gas emissions from tank batteries at 6 ton per year (tpy) of VOCs and 20 tpy methane. Any tank batteries emitting equal to or greater than the limit must use a control device to reduce emissions by 95% or greater. Common control devices used in these cases are Vapor Recovery Units (VRUs).

There are updated standards covering gas compressors in OOOOb. For centrifugal compressors, OOOO and OOOOa stipulated that vents of any wet-seals had to route to a control device or capture the emissions in a recovery unit and dry-seal units had no requirements. Under OOOOb, both wet- and dry-seal centrifugal compressors have limits on the seal flow rate and annual monitoring must be performed to ensure compliance with these limits.

Reciprocating compressors have also been impacted by the recent changes. Under OOOO and OOOOa, rod packing must be replaced every 36 months or 26,000 hours of operation. Under OOOOb, a flow limit has been placed on the packing vents and annual monitoring unless the rod packing is changed every 8,760 hours of operation.

Notable Changes Under OOOOc

OOOOc does not directly regulate designated facilities, but has created a model rule language that is not mandatory, but can be used as part of a state plan. The state plan must be at least as protective as the model rule. It requires states to hold public hearings, document meaningful engagement, and submit plans to address existing sources by March 8, 2026. Assuming approval of the state plan by the EPA, facility compliance with the state plan is required within 36 months after submission. If an approvable state plan is not submitted, the EPA is obligated to issue a federal plan.

Under OOOOc, flaring is permitted for pre-existing wells with documented methane emissions of 40 tons per year or less, so long as that gas is routed to a flare or control device that achieves a 95% reduction in methane.

Super Emitter Program

The recent changes have also put into motion a Super Emitter Program. When a Super Emitter event occurs, the responsible party receives notice from the EPA and must investigate within 5 calendar days and report back to the EPA with information about their asset. A Super Emitter event is an emission event that is >100 kg/hr and may have emitted from an affected facility or associated equipment subject to regulation under OOOO, OOOOa, or OOOOb. These events may be reported based on information from a certified third party and that is detected using remote detection methods.

Rule Application Details by Site

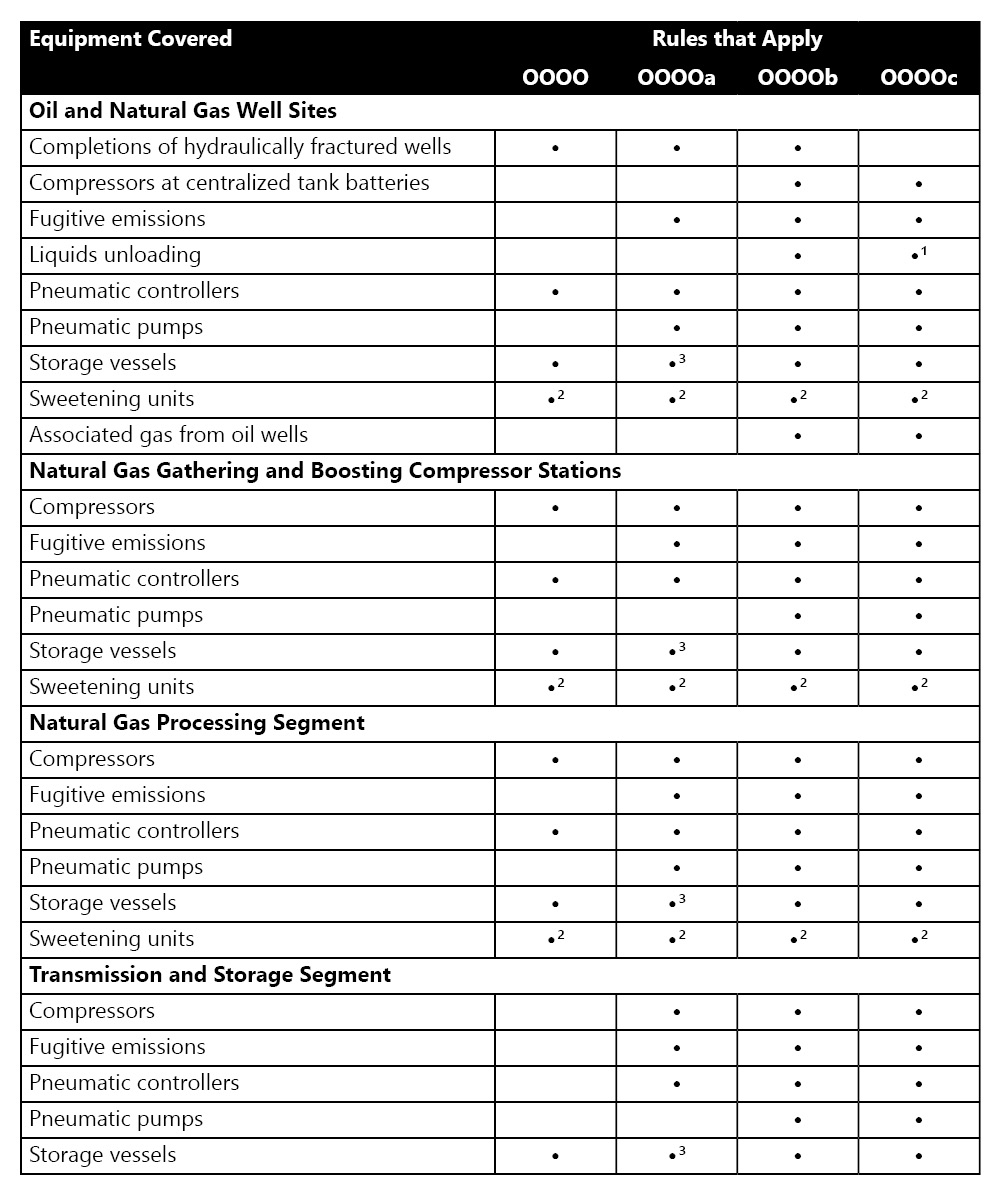

To provide greater detail on this progressive expansion of the rule, the table below breaks up the different sources into categories and lists which rule applies to each source type.

All the sources listed above are covered by the Super Emitter Program.

●1 Added in 2022 supplemental proposal

●2 Covered for SO2 only

●3 Covered for VOCs only

What’s the Deal with Quad-O?

Broadly, the goal of the rule is to reduce emissions and improve air quality toward the original vision of the Clean Air Act. It encourages innovation to advance monitoring technologies to identify leaks and fugitive emissions across upstream and midstream operations. The EPA estimates Quad-O implementation will lead to a reduction of 58 million tons of methane, 16 million tons of smog-forming VOCs, and 590,000 tons of air toxics like benzene.

Flow Measurement Solutions to Quad-O Challenges

Compliance with Quad-O may present several challenges to operators when taking into consideration the remaining useful life or restricted capacity of some source types. There may be physical or technical difficulties of installing monitoring and control equipment. First, operators must ensure monitoring devices meet the letter of METHOD 2D. Some considerations include the cost, pressure and temperature measurements, and ease of installation of flow monitoring devices.

Fox Thermal mass flow meters offer valuable solutions:

- Direct mass flow rate of gases

- No additional pressure or temperature compensation required

- Repeatability and exceptionally broad measurement range: up to 1000:1 (100:1 typical)

- Low pressure drop

- Cost-effective gas flow meters with fast lead times

- Calibration validation tests can be performed at any time to ensure the meter still retains NIST-traceable calibration

- Advanced data logger on model FT4X for record-keeping

Fox Thermal calibrates and programs all thermal mass flow meters to process-specific gases. The meters correct flow rates to standard conditions independent of pressure and temperature, so additional pressure or temperature measurement is not required.

To learn more about gas flow meters used for Quad-O compliance, request a quote or a product demonstration.

Quad-O for Flares, Vent Gas, and Gas Compressor Packing Leaks

If you’d like to check out more information on our flow meters for flare gas, vent gas monitoring from tank batteries, or gas compressor packing leaks, use one of the links below.

If you're ready to get a flow meter to optimize your process, get started with our online product selector tool here: Help Me Choose

Sources:

40 CFR Part 60 Subpart OOOO Published in the Federal Register

https://www.epa.gov/system/files/documents/2023-12/summary-of-key-requirements-table.pdf

METHOD 2D—MEASUREMENT OF GAS VOLUME FLOW RATES IN SMALL PIPES AND DUCTS