Accurate flow measurement is foundational to operational excellence, especially in separator systems. Whether you’re dealing with gas, water, or multi-phase streams, reliable data drives production performance, environmental compliance, and cost control. That’s why we’re excited to showcase the latest insights from Fox Thermal in the newly released “Separator Application Optimizer.”

THE CRITICAL ROLE OF FLOW IN SEPARATOR APPLICATIONS

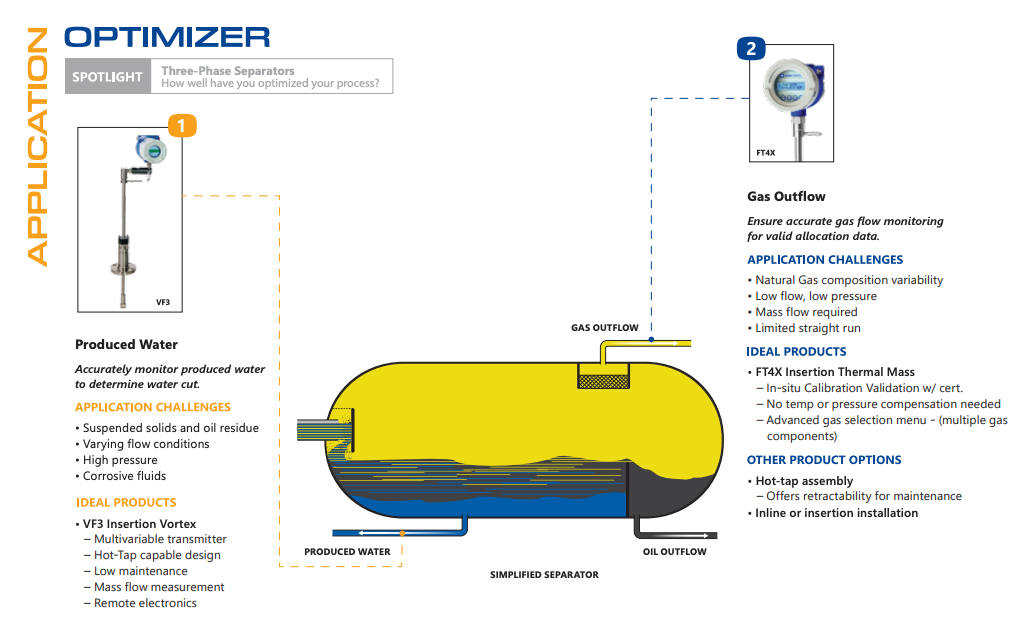

Separator systems, especially three-phase separators, manage streams of oil, gas, and produced water. But without precise flow measurement, you risk inaccurate allocation, inefficient separation, and increased operational risk. According to Fox Thermal, flow meters tailored for gas and produced-water outlets play a major role in achieving process stability, meeting emissions requirements, and protecting asset integrity.

With thermal gas mass flow technology, you gain direct mass flow measurement of natural or fuel gas, which is crucial for monitoring vent or gas-outflow in separators, minimizing flaring, and supporting revenue assurance.

COMMON CHALLENGES IN SEPARATOR APPLICATIONS

Separator environments bring multiple measurement challenges:

-

Flow rates may vary widely as wellhead conditions change, making meter selection and turndown critical.

-

Gas composition shifts or water carryover can affect meter accuracy if the technology is not designed for such complexity.

-

Produced-water streams often contain oil, solids, or entrained gas, which can foul or bias measurement devices.

-

Installation constraints, such as limited straight-run piping or retrofit layouts, can force difficult meter placement.

-

Downstream compliance and allocation demands place pressure on measurement quality and traceability.

In the oil-and-gas context, Fox Thermal emphasizes that accurate measurement at both gas and water outlets of separators enables better production tracking, more reliable allocation, and improved operational performance.

HOW THE SEPARATOR APPLICATION OPTIMIZER HELPS

The “Separator Application Optimizer” is a practical guide that walks you through technology selection and application strategies for separator measurement. Key takeaways include:

-

Selecting thermal mass flow and vortex-shedding meters that are built for demanding conditions such as high pressure, multi-phase fluids and gas-water interfaces.

-

Using hot-tap or insertion/inline meters to reduce installation downtime and maintain leverage in retrofit environments.

-

Implementing remote electronics and in-situ calibration validation features to ensure long-term accuracy and ease of maintenance.

-

Adapting to changing gas compositions via menu-selectable options in the meter, which prevents recalibration-induced downtime. Fox Thermal

-

Establishing a flow measurement regime that supports allocation, emissions reporting and production accountability.

These features align closely with TechStar’s commitment: from technology selection to facility mapping, we support clients in installing robust flow measurement systems that deliver real-world results.

BENEFITS FOR YOUR PROCESS

When you integrate the right meter technology and application strategy in separator systems, you unlock measurable benefits:

-

More reliable allocation of gas and produced water, leading to better production management and cost control.

-

Reduced emissions and better regulatory alignment as you measure gas outflow and water volumes more effectively.

-

Improved equipment uptime and reduced maintenance burden, thanks to rugged meters, hot-tap capability, and remote validation.

-

Enhanced process optimization: when you know accurate flow rates, you can fine-tune separation conditions (pressure, temperature, throughput) and extract more value from your system.

At TechStar, we view this as part of our commitment to delivering value. We don't simply recommend a meter, but guide your team through measurement selection, installation planning, and long-term monitoring. Get in contact with your local TechStar Subject Matter Expert.

Next Steps

If separator flow measurement is a priority for your facility, here’s what to do:

-

Download the “Separator Application Optimizer” from Fox Thermal and review it alongside your current measurement setup.

-

Contact TechStar’s flow instrumentation team to evaluate your system: meter choice, installation layout, calibration practices, and maintenance strategy.

-

Consider upgrading to thermal gas mass flow meters from Fox Thermal with features such as menu-selectable gas compositions, data logging, and calibration validation.

-

Set benchmarks: establish baseline flow accuracy, track improvements in uptime or allocation, and build a measurement-improvement roadmap.

If you want to talk through how TechStar can support your separator flow measurement projects, from design through commissioning and beyond, we’re ready. Let’s turn measurement theory into real-world performance together.