How Big Data Analytics is Used in Oil and Gas Refineries

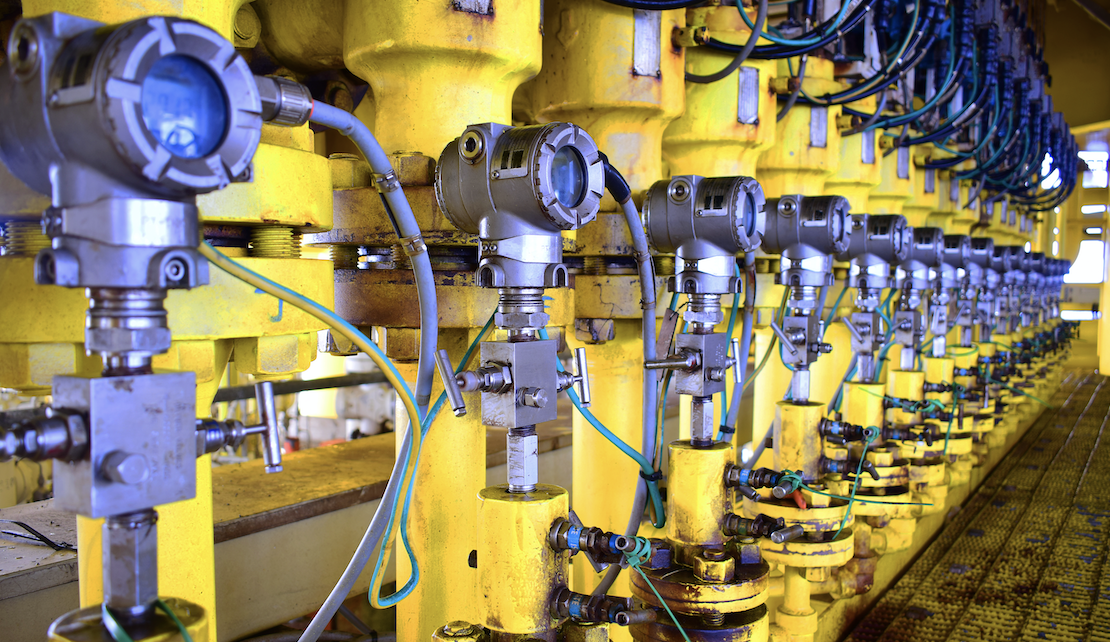

Big data analytics is transforming the oil and gas refinery industry. Oil and gas refineries generate large amounts of data that include equipment insights, maintenance reports, performance measurements, and more. Those monumental volumes of data must be processed and analyzed in order to deliver value. While refineries have been using organizational and analytical tools for a very long time, big data oil and gas offers innovative solutions that can make the industry more efficient and profitable. In light of volatile changes in supply and demand, oil and gas big data analytics can help companies improve their operations and sustain a competitive advantage. For refineries, big data analytics can enhance and improve the process control systems, manufacturing processes, emergency shutdown systems, equipment interfaces, laboratory information system, online analyzers, asset management systems, and more.