Gas detection controllers are used in a wide variety of industrial and commercial applications where fire, smoke, and/or toxic gases can present a potential hazard to property or threat to personnel. Controllers are designed to work with one or more gas detectors that provide permanent and continuous monitoring and generate actions in case of gas detection.

Gas Detection Controller: How it Works, Types, & Importance

Topics: techstar

Your Refinery Has Options When Revamping Delayed Coker Units

Your refinery has options when revamping Delayed Coker Units. This was recently realized for a customer of ours, one of the biggest refineries in the United States. They have two delayed coking units. DCU 1 which consist of a 4 drum coker and DCU 2, which consist of a 6 drum coker. All 10 drums currently were using our competitors level system for measurements.

Topics: Level Solutions, Berthold

Advantages of Sensor Technology: Accuracy and Meter Calibration

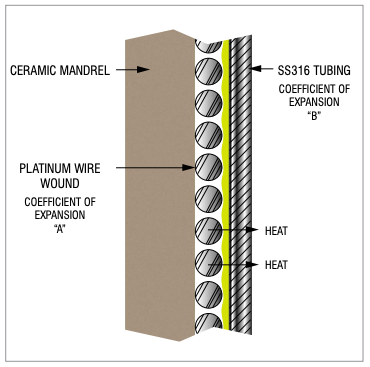

The accuracy of a thermal mass flow meter is dependent upon the technology type and the quality of the materials used for the meter’s sensor design. A well-designed sensor is made to measure flow accurately over a long period of time with minimal drift, independent of recalibration and calibration validation diagnostics. For a thermal mass flow meter, the materials used in the manufacture of the sensor play a vital role in the overall performance of the sensor. The materials must create the best environment for heat transfer - the essential principle of thermal mass flow measurement - or the accuracy and response time suffer.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, flow

Hot-wet continuous emission monitoring (CEM) measurement means analyzing the stack gas sample on an as-is basis, which ensures that the integrity of the sample, from extraction through analysis, is maintained. Keeping a good heat integrity in hot-wet measurement is very important to prevent the condensation of acid mist or water vapor.

Topics: AMETEK Process Instruments, Analyzer

Over the last 25 years, there have been significant advancements in level measurement technology. Accuracy, repeatability, linearity, resolution, and reliability have all seen step-change advances as digital signal processing (DSP), power management, and microprocessor improvements have led to advancements in instrumentation with the end result of creating more value for end users on a cost per point basis. Those advances have enabled companies, plants and operators to consider new and unique ways to deploy instrumentation. One choice, which has seen more use, is the utilization of modular instrumentation bridles which allow for flexibility, adaptability and customization, in greenfield or brownfield situations. This article will address some of the benefits and challenges associated with bridle measurement.

A bridle is an externally mounted chamber (via process connections) with the ability to accommodate a variety of process connections allowing for a wide variety of instrumentation[PW1] , including. Bridles can be isolated from the main tank using valves which allows for maintenance (if allowed by the plant) without interrupting the process. Instrument bridles are commonly outfitted with level switches and/or continuous level transmitter technology including (but not limited to) Guided Wave Radar, Magnetostrictive and Displacers. This post will also address Magnetic Level Indicators (MLI), which are a popular form of externally mounted visual indication.

Interface Measurement in a Bridle

A tank filled with two different liquids is common in the process industries. Typically, a bridle will have two process connections, but in a liquid-liquid interface application, if the bridle is not operated under flooded conditions (liquid reaching the upper process connection), the upper liquid layer may become trapped on top of the lower layer with no way out. The fluid levels will balance based on density, but since the upper material would be lighter than water, the levels in the chamber and vessel will not be the same. This error will be proportional to the Specific Gravity (S.G.) difference between the two fluids. A common solution to this problem is to add a third (middle) process connection and a good rule of thumb is to ensure that each fluid is in contact with a process connection at all times.

Another liquid-liquid interface challenge that can arise is the presence of an emulsion layer. Particularly in applications with a short retention time in the vessel, the two liquids can mix together and form a rag or emulsion layer. Depending on the application and the medias, an emulsion layer can range in size from a few inches to several feet. The S.G. gradient that exists within this layer can challenge density-based measurement devices such as displacers and float-based MLIs. However, MLI floats can be designed so they sink through the upper liquid layer and float on the lower layer. Even in the presence of a large emulsion layer, the float would position itself within the layer and continuously provide indication of the float location. Do we want to clarify this by indicating minimum SG delta’s and also float length (floats can interfere with each other if there is not enough space between the floats to move freely)

Effects of Temperature on Level Measurement

When an MLI or bridle is connected to the side of a vessel, a temperature difference in the liquid can be expected. Depending on the media, the density can increase or decrease, which sometimes results in a slight measurement error. For example, hot water in a vessel would be slightly cooler in an offset or externally mounted bridle or MLI. The liquid level in the bridle would be marginally lower than in the vessel because its density has been increased due to the cooling. Ambient temperatures play a major role in determining the severity of this gradient. In the hot water example, the gradient would be much more pronounced in the winter season versus the summer. Anyone specifying an MLI or bridle-mounted instrumentation should be aware of this effect, as well as understand the expected temperature gradient for each installation.

When utilizing buoyancy-based technologies, the measurement in the MLI or bridle will be affected when the media density changes. With an MLI, the float is typically designed for one S.G. If the float design is based off of the S.G. of the liquid in the vessel, the float would experience a small offset when the liquid enters the MLI. This is particularly important on start-up. This is because the cooled liquid in the MLI now has a higher density than what the float was designed for and this higher density will cause the float to sit higher than normal in the liquid. Orion Instruments can provide accessories for its level instruments to help mitigate this temperature effect; these include insulation, heat tracing, or a float projection curve used to anticipate error due to S.G. variation.

In conclusion, it’s important to understand how properties such as temperature, density, and distance have an effect on level measurement in bridles. In most cases, the realized error is marginal; however, it is worth the effort to understand what potential changes you can expect in your process.

Topics: Level Solutions, Magnetrol, Orion Instruments, MLI

Chart Recorders: Definition, Types, Uses, and How to Choose

What is a chart recorder?

A chart recorder is an instrument that records electrical and process signals. Traditionally, chart records are built of a piece of paper and a pen that creates marks in response to a signal.

Online vs Hands-On: Which is best for technical training?

What happens in online technical training?

In online technical training, students can watch live or recorded talks that cover in-depth analysis of applications, solutions, and the overall process industry. Online technical training can also include interactive sessions where students can ask questions and participate in discussions in real time.

THE UNIT: Why Use a Hands-On Technical Training Facility

What is THE UNIT?

THE UNIT is a training and development solution that provides application-specific hands-on experience. The Functional Verification Unit is a training facility site for companies to conduct process-specific, interactive training without interrupting in-house production. At THE UNIT, TechStar offers customizable technical training resources to mimic your specific process conditions, testing, and troubleshooting. The controlled environment is ideal for small group sessions to onboard new personnel, train team members for specific products, and conduct mandatory recertification to maintain compliance. Check out this video to see the fully functional live unit, innovative level solutions, reliable flow measurement, process automation, custom cabinets and enclosures, technical courses, custom sessions, hands-on training, engaging classroom instruction, a full range of instruments and devices, and more.

Keeping Astronauts Safe on the International Space Station

Now onboard the International Space Station (ISS), MSA Safety's combustible gas sensors are part of NASA's Advanced Hydrogen Sensor Technology Demonstration. The system is testing new ways to keep astronauts safe by detecting hydrogen, a highly flammable gas.

Topics: MSA, Gas Detection Solutions, Safety

Hand-on Technical Training for Process, Instrumentation, and Controls

Providing necessary training for workers is one way for organizations to ensure their employees can appropriately perform their jobs to an organization’s standards. While technical training is needed across a broad range of industries, from software engineering to accounting to marketing, in this article, we’ll be looking at hands-on training for process, instrumentation, and controls. Training in these industries requires hands-on training because workers are using highly specialized machines and equipment.