Our instrumentation & analytical solutions are critical to the day-to-day operation and overall success of your process. Understanding that downtime is simply not an option, we have a new system in place to ensure your process is prepared for the unexpected. Introducing TechStar One Click, our new eCommerce purchasing option.

Optimize Your Process: Innovative Solutions In One Click

Topics: Level Solutions, Signal Conditioning and Isolation Solutions, Wireless and Telemetry Solutions, Pressure Solutions, Upstream Solutions, Flow Solutions, TechStar One Click

Direct Mass Measurement of Flare & Combustor Gas Flow Rates

Providing exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

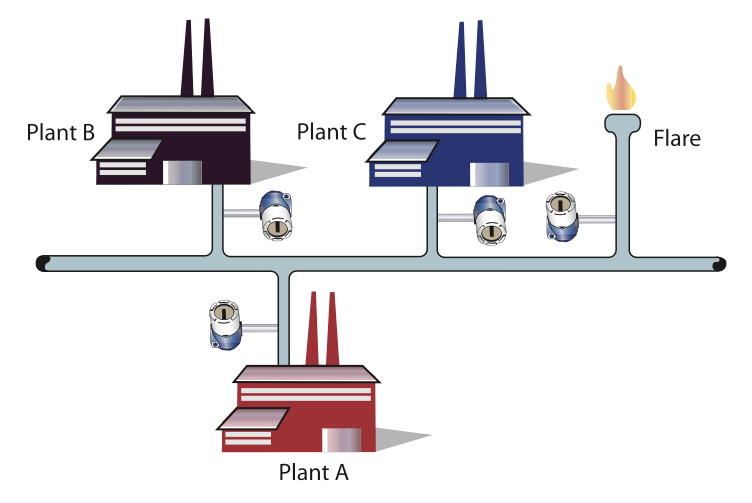

Flare stacks and combustors are used to burn waste gases from the plant, converting chemical and organic hydrocarbons into primarily water vapor and CO2. Some processes also use relief valves to vent flammable gases to the flare stack during upset conditions.

Applications include oil and gas well drilling operations, oil refineries, chemical process plants, gas distribution infrastructure, and landfills. Flares are subject to stringent regulations, requiring operators to measure, record and report the amount of flared gases.

Due to the potential for large changes in flow rates, density, pressure and gas composition, flare gas measurement is one of the most difficult and demanding flow applications. Fox Thermal flow meters have demonstrated their ability to measure the low-flow rates typical of normal flare conditions, and also the high velocities found in upset conditions.

Fluid composition and installation anomalies can also affect flow meter performance. Fox Thermal's calibration lab employs a wide range of gases, gas mixtures, temperatures, pressures and line sizes to simulate actual fluid and process conditions. This real-world approach improves installed accuracy and minimizes measurement uncertainty.

Fox Flow Meter Advantages in Emissions Monitoring Applications

-

Exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

-

Stainless steel sensor is suitable for corrosive, particulate-laden gas streams

-

No temperature and pressure compensation required

-

Direct mass flow measurement

-

Built-in alarms, totalizers and a wide variety of communications protocols available for easy interfacing with emissions management systems

-

Oil and Gas Well Drilling Operations (On and Off shore)

-

Oil Refineries

-

Chemical/Petrochemical Processing Plants

-

Gas Distribution Infrastructure

-

Landfills

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, Flare Gas

Custody Transfer Flowmeters – An Evolution in Technology

Custody Transfer (also known as Fiscal Metering) in the oil & gas industry refers to the transactional transfer of a substance, raw or refined, from one party (owner) to another.

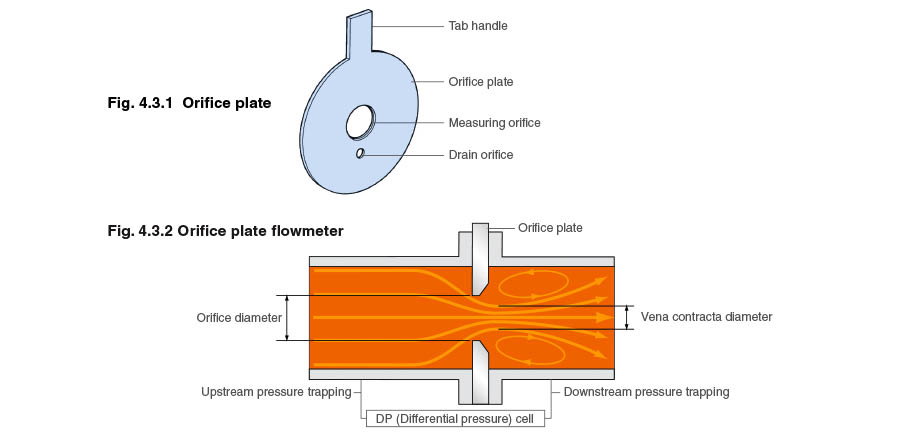

Typically when a custody transfer is taking place, the end goal is to determine the value or payment between two parties for the physical substance (gas or liquid) that has exchanged hands via pipeline. For that reason, the flow instrument that measures the total amount of product changing ownership can be viewed as a cash register between the two parties.

Topics: Flow Solutions

This blog was originally posted by Yokogawa.

Optimum control of production to avoid unnecessary costs

Raw materials and end products are accepted, processed, stored and delivered in almost all industrial processes. In order to optimally control production while avoiding unnecessary costs and ensuring product quality, the volume flows must be recorded correctly and seamlessly. This task should be solved as precisely as possible and with minimum pressure losses. The application-specific parameters must, of course, be taken into account, such as the type and composition of the medium to be measured, process pressure and temperature range.

Topics: Yokogawa, Flow Solutions

Applications and Industries for Thermal Mass Flow Meters

This blog was originally posted by Fox Thermal.

Fox Thermal manufactures a full line of advanced thermal mass flow meters. Each flow meter is manufactured to strict quality standards, calibrated to NIST standards in their state-of-the-art calibration labs, and customized for your application needs.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions