Excessive gas consumption wastes money - and of greater importance - can affect product quality and safety. The pharmaceutical industry uses large quantities of nitrogen, oxygen, carbon dioxide gas, and air. Without good air and gas flow measurement, cost, quality, and consumer safety will suffer.

4 Reasons Thermal Mass Flow Meters Make Sense in Pharmaceutical

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Pharmaceutical

Direct Mass Measurement of Flare & Combustor Gas Flow Rates

Providing exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

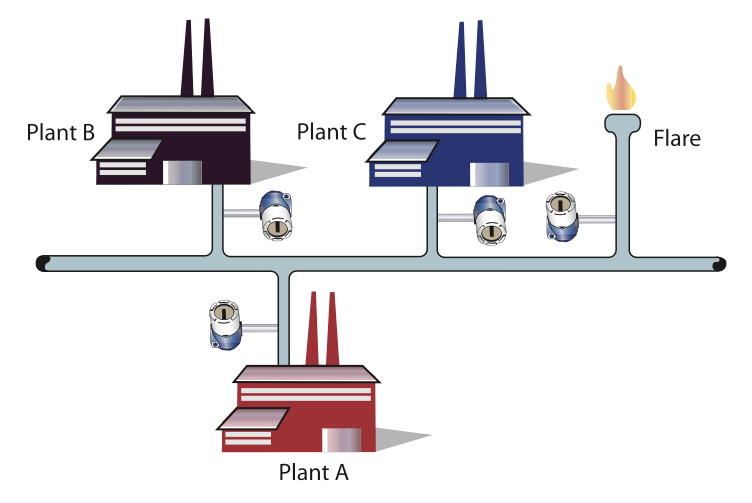

Flare stacks and combustors are used to burn waste gases from the plant, converting chemical and organic hydrocarbons into primarily water vapor and CO2. Some processes also use relief valves to vent flammable gases to the flare stack during upset conditions.

Applications include oil and gas well drilling operations, oil refineries, chemical process plants, gas distribution infrastructure, and landfills. Flares are subject to stringent regulations, requiring operators to measure, record and report the amount of flared gases.

Due to the potential for large changes in flow rates, density, pressure and gas composition, flare gas measurement is one of the most difficult and demanding flow applications. Fox Thermal flow meters have demonstrated their ability to measure the low-flow rates typical of normal flare conditions, and also the high velocities found in upset conditions.

Fluid composition and installation anomalies can also affect flow meter performance. Fox Thermal's calibration lab employs a wide range of gases, gas mixtures, temperatures, pressures and line sizes to simulate actual fluid and process conditions. This real-world approach improves installed accuracy and minimizes measurement uncertainty.

Fox Flow Meter Advantages in Emissions Monitoring Applications

-

Exceptional low-flow sensitivity for accurate measurement over a wide range of flaring operations

-

Stainless steel sensor is suitable for corrosive, particulate-laden gas streams

-

No temperature and pressure compensation required

-

Direct mass flow measurement

-

Built-in alarms, totalizers and a wide variety of communications protocols available for easy interfacing with emissions management systems

-

Oil and Gas Well Drilling Operations (On and Off shore)

-

Oil Refineries

-

Chemical/Petrochemical Processing Plants

-

Gas Distribution Infrastructure

-

Landfills

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions, Flare Gas

Applications and Industries for Thermal Mass Flow Meters

This blog was originally posted by Fox Thermal.

Fox Thermal manufactures a full line of advanced thermal mass flow meters. Each flow meter is manufactured to strict quality standards, calibrated to NIST standards in their state-of-the-art calibration labs, and customized for your application needs.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters, Flow Solutions

Fox Thermal Case Study: Thermal Flow Meter Calibration for Natural Gas Services

A study of the importance of gas composition and calibration and their effects on flow meter accuracy.

Topics: Flow Meter Solutions, Fox Thermal, Thermal Gas Mass Flow Meters

WHITEPAPER: Reduce Energy Costs and Enhance Emissions Monitoring Systems

A Technical White Paper from Fox Thermal Instruments.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters

Topics: Fox Thermal, Thermal Gas Mass Flow Meters

Benefits of Thermal Gas Mass Flow Meters Over Other Flow Measurement Technologies

There are many benefits to using Thermal Mass Gas Flow Meters over other flow measurement technologies.

Topics: Fox Thermal, Thermal Gas Mass Flow Meters