This blog was originally posted by Yokogawa.

Alarm management has increasingly become a hot topic over recent years, not least because of a number of high-profile accidents where alarms have been implicated. It often requires significant investment in time and resources when applied to an existing control system and there is a need for continuing review for it to remain effective. Yet an increasing number of companies are embracing alarm management for one or more reasons. So what are these reasons, why manage alarms given all the other conflicting pressures on time, and what are the benefits for those who make the journey?

First of all there are safety benefits for companies both onshore and offshore. In my experience an alarm management program often results in enhanced understanding of abnormal process conditions and consequently faster, more appropriate corrective action. This can lead to shorter outages (or even avoid outages!) and in extreme cases could mean the difference between life and death. There are good reasons why companies take safety very seriously, and an increasing number are actively reviewing alarm handling as part of their safety management systems.

There is also a clear regulatory driver. The HSE in the UK (and regulators in other countries) is very aware of the human factors issues and has been known to use EEMUA 191 (a guidance document still widely recognized as the embodiment of good practice for alarm management) in specifying improvement targets. Their position was made very clear a few years ago in the following extract from an article entitled “Better alarm handling – a practical application of human factors” by John Wilkinson and Dr Debbie Lucas of the HSE:

“The key message is that it is never going to be acceptable to conduct one review and implement the conclusions. This has to be part of a continuous process of improvement, just as it is with most other business areas such as quality. Why manage safety any differently?” This largely remains the HSE’s stance. EEMUA 191 is also being used by insurance companies Worldwide as a benchmark of good practice when assessing the performance and operating culture of process companies.

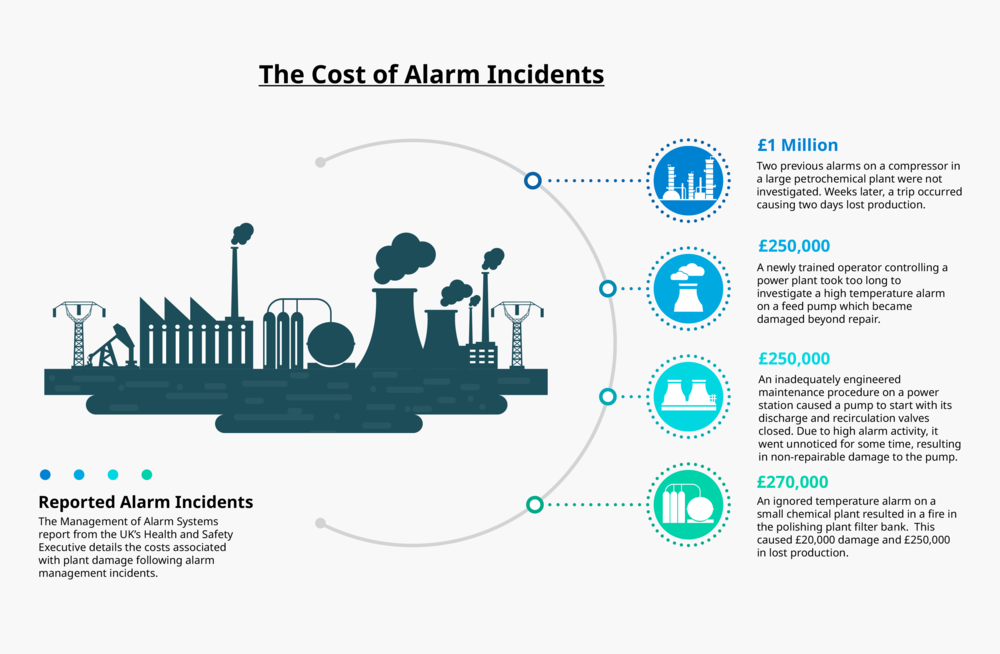

There are definite economic benefits. Alarm handling systems are a significant source of information for process operators and alarm rationalization and management initiatives typically help to improve understanding of process behavior. This results in higher quality information for process operators in the control room and where this information is used effectively it can yield greater product consistency, higher throughput and better-targeted maintenance.

Environmental benefits tend to be more difficult to identify but are undoubtedly there. Any initiative that results in improved process stability and fewer upsets should result in fewer accidental releases, and alarm management has a clear contribution to environmental protection.

Where alarm systems have been implicated in an incident it is normally the human factors elements that have been found to be at fault. Any exercise in operator job design and ergonomics should therefore include a review of the alarm system’s human-machine interface and assess its fitness for purpose, including its contribution to operator stress. Consider the design of aircraft cockpits for example and how information (including alarm information!) is presented to pilots – it seems likely that the process industries could learn something here.

Research has shown that the drivers behind alarm management programs are most frequently related to safety, economic, or environmental protection (in that order) with an element of regulatory pressure. Respondents from a cross-section of the process industries reported either ‘appreciable’ or ‘substantial’ benefit and nobody reported zero benefit from their initiatives. As already discussed, this is not really surprising.

In summary, alarm management is an exercise in continuous improvement, not a one-off initiative to be implemented and then neglected. The exercise can be more costly when carried out retrospectively but there are still significant benefits to be had, and these usually far outweigh the costs. So why manage alarms? The message seems clear that this is part of the management planning for a facility and should be good for business.