A common problem in the oil and gas industry is unreliable readings causing false alarms that cost millions of dollars in lost revenue annually. Safety systems triggered by the detection of potentially hazardous gases typically shut down processes and facilities to prevent a potential catastrophe. But when a false alarm triggers the safety system, productivity is lost while the alarm origin is investigated, false alarm status is verified, and processes are slowly brought back online.

High false alarm rates, slow detection, and poor reliability are problems that frequently plague work site operations when dealing with traditional NDIR or LDS-based open path gas detection systems and specifically in toxic gas leak detection applications.

A detector with a greater detection range is generally considered an advantage since it means a greater ability to detect the hazard either earlier or from greater distances. However, it is important that the detector does not lead to an increased incidence of false alarms.

Enhanced Laser Diode Spectroscopy (ELDSTM) is a newer class of laser diode spectroscopy for gas detection that significantly increases the sensitivity and reliability of traditional laser-diode-based gas detection and measurement, even in extreme environments.

ELDSTM laser-based gas detection is gas species specific and will only respond to the target gas.

This removes any cross interference and unwanted alarms. Currently, ELDSTMproducts are available for Ammonia, Carbon Dioxide, Hydrogen Sulfide, Hydrogen Chloride, Hydrogen Fluoride, and Hydrogen Sulfide.

There is also a detector capable of detecting both Hydrogen Sulphide and Methane in one device. Each of the two detection channels is configured and specific to the target gas.

Three big benefits of ELDSTM over conventional toxic detectors are:

- Elimination of false alarms

- Failsafe operation

- Reduced maintenance

Elimination of false alarms

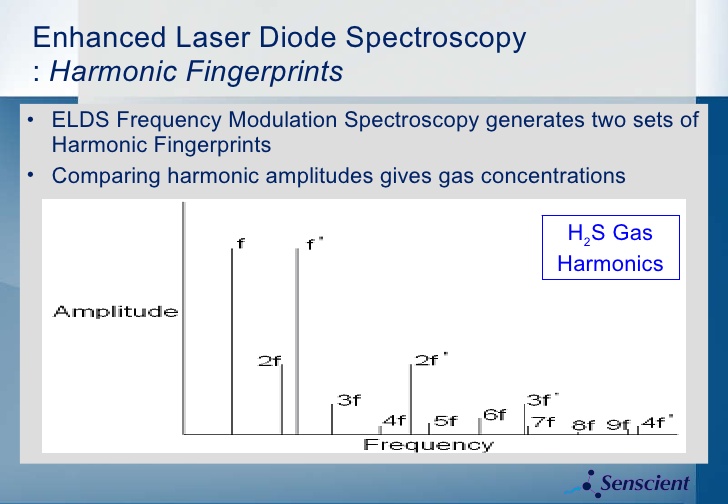

Key to the elimination of false alarms is a harmonic fingerprint detection method. A Harmonic Fingerprint is a specific set of harmonic components introduced by target gas absorption where the relative amplitudes and phases of the components are known and specific to the target gas absorption line that is being scanned. This technique eliminates the distortion and interference that typically affect conventional laser diode spectroscopy (LDS). The harmonic fingerprint means that you can reliably distinguish between genuine target gas and non-target-gas effects. In addition, this technology is less prone to water vapor interference, thus reducing the negative repercussions of false alarms while improving detection capability for general plant safety. This is a link to a short Video showing how the technology is applied.

Failsafe operation

Most fixed gas detectors do not provide the end-user with live information on the operational status of any device whereas the ELDS uses a daily auto-self test called SimuGas which is a unique auto-test feature available on all units. This test provides daily verification of the system's operation without the need for manual intervention or the need for externally applied test gas or optical filters. As well as providing an alarm in the event of a test failure, each test result is held in an internal event log for future retrieval.

For example; a common trait of solid-state semiconductor sensors is their tendency to “go to sleep” when exposed to H2S-free air for prolonged periods of time while ELDS will respond to H2S after long periods of H2S-free exposure.

Electrochemical sensors are effective in detecting H2S gas, yet they are not resilient in high heat and prolonged low or high humidity conditions.

Reduced Maintenance

The reduction in maintenance is achieved in at least two ways. One; ELDSTM does not have any consumable parts unlike other fixed point gas detectors, which need their sensing elements replaced on a regular basis. This saves the cost associated with spares and service labor.

In addition; the SimuGas auto-self test provides integral, daily auto-self-testing information, negating the need for regular manual testing using test gases and all associated costs. Gas detector functional testing is the bane of operators responsible for maintaining conventional fixed gas detection systems yet it is essential for ensuring the safety integrity of an entire system. The SimuGas technology provides operators with the means to perform remote, on-command functional testing of an ELDS gas detector more easily, safely, and less expensively than with traditional laser diode spectroscopy gas detector technologies or point detectors.

Our conclusion is that Enhanced Laser Diode Spectroscopy can be utilized to improve the performance and safety of toxic gas detection systems, eliminate lost production resulting from false alarms and reduce maintenance costs. Additional information on permanent gas monitoring is available in the MSA Gas Detection Handbook.

Please let us know what your thoughts and comments?