Trace moisture measurements in gas applications often appear to be simple and straight forward because the theory is relatively well understood; however, when the analyzer system is in service and we see unexpected measurement results, the head scratching begins.

Electrically everything appears to be correct so we assume the probe/sensor must be out of specification, right???

Changing the sensor is not the best first action. There are other key aspects that should be checked and confirmed first. Low dew point ranges make every detail critical. You are actually measuring molecules so attention to the fine points will be beneficial.

Pressure, temperature and flow rate as well as the analyzer configuration have a significant effect on the resulting measurement because you are measuring a very small component of the total sample. The sample conditioning system design and operation are just as important as the analyzer and sensor. You might consider these nine common points before going to the expense of changing probes.

- The sampling system should be allowed to equilibrate for up to (typically) 24 hours following exposure to ambient moisture (atmospheric air).

- 80% of the dry-down can be reached in a few minutes yet the last 10%-20% of dry-down can take hours.

- The lower the true dew point is, the longer equilibrium can take.

- A purge‐type flowmeter aids in determining equilibration point and will aid in qualifying the integrity of seals.

- If the hygrometer reading changes with a change of flow rate, one or more of the following is to blame:

- saturation-indices (this is a subject we plan to discuss in a separate blog)

- System is leaking

- System is dirty

- If the hygrometer reading changes with a change of flow rate, one or more of the following is to blame:

- Measurements should be made at system pressure or the highest possible pressure to minimize outgassing of metal parts, wall effects, etc., which will result in higher dew points with increased sensitivity.Other things to remember in regards to pressure and temperature effects:

- It’s necessary to convert readings taken at atmosphere to equivalent dew point at line pressure if line pressure dew point is what you want, or vice versa.

- For example, ‐40F (-40C) dew point at 100‐psig line pressure is 16.2 PPMv and equal to ‐70.4F (-56.9C) dew point and 16.2 PPMv at atmosphere pressure.

- We intend to discus “partial pressure measurements” and Dalton’s law of partial pressures in an a future blog post.

- Diffusion of atmospheric water vapor is always present. Even if a “pigtail” discharge system is fashioned, with a throttle valve at the end, the diffusion is only minimized. Results are influenced so much by ambient conditions that the precise measurement of low (less than ‐60C) moisture levels may be very difficult and require attention to good technique.

- Be aware of the diurnal (day/night) effect. This effect produces a true change in moisture content due to heating/cooling of process surfaces.

- It’s necessary to convert readings taken at atmosphere to equivalent dew point at line pressure if line pressure dew point is what you want, or vice versa.

- Any cross-checking between two or more similar instruments should be done at identical time and conditions.

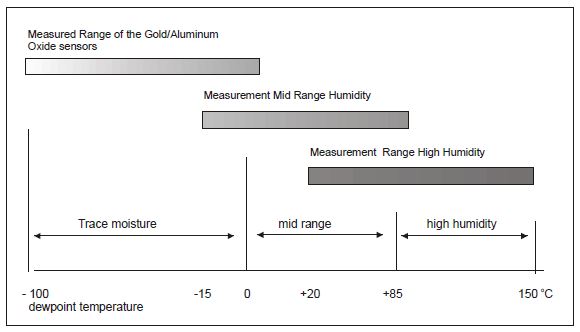

- This is even more important when dissimilar measurement technologies are compared. It is not possible to use some makes of moisture meters under flowing conditions (in situ) on stream or at line pressures. Some are unstable or are affected by temperature changes and other variables.

- Cleanliness is essential. Manufactures’ specifications on probe cleaning, sampling and measuring techniques, and interpretation of data should be followed to the letter.

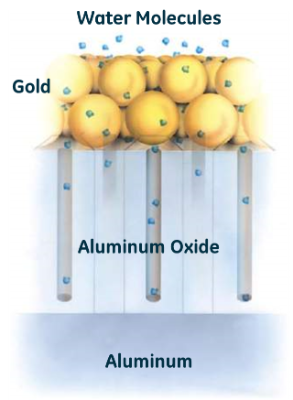

- Some contaminants can cause false readings or deactivate the probe. The system will have to dry out before data can be taken again. Remember sample must be chemically compatible with aluminum or the sensor will fail.

- Cleaning an aluminum oxide sensor is relatively simple. All you need is reagent grade hexane or toluene and deionized water.

- Recalibration should be performed every 12 months or sooner based on your experience in the specific application. There should always be spare probes available. This allows checking probes against another and avoids having the analyzer out of service when the probes are being recalibrated.

- Engage the process specialist or other resources to assure a common understanding of the process conditions. Everyone involved should be as knowledgeable as possible on the difficulties of moisture measurement, the use of equipment and the meaning of data.

- Define problems carefully. The right approach to equipment selection and measurement techniques will instill confidence in the end results. Remember you are dealing with a pressure gauge when interpreting sample system phenomenon. The dew point is effected by the pressure the sensor is experiencing. If the sample pressure goes down, the measured dew point of the sample will go down also.

- Remain open to the possibility that an unexpected dew point is actually correct and something could be amiss with the process itself. A perfectly functioning analyzer system is unbiased. It simply reports what it experiences.

Everyone involved in testing the analyzer system – process engineers, operators and technicians – should be as knowledgeable as possible on the challenges of moisture measurement, the use of equipment and the meaning of the data.

Do not be afraid to ask questions or for support from your vendor, equipment manufacturer or to reach out to us. It is likely we have previously experienced something similar to your questions.